Losi Hammer Rey Rock Racer

|

Welcome to our new section dedicated to the Losi Hammer Rey U4 Rock Racer. This RTR is modeled around Casey Currie's Trophy Jeep which he's used to collect a number of impressive wins in the Ultra 4 and King of the Hammers race series.

Our primary focus was to evaluate how well the Hammer Rey performs on our rugged desert track, and how long it will tolerate the difficult, rocky terrain before completely falling apart. We did not partake in any bashing, jumping, or doing any “top speed” asphalt runs with the Hammer Rey. For the MVRCA group, it’s all about Ultra 4 styled off-road racing. |

|

The Hammer Rey project came together with the help of our good friend Oscar T. from SoCal as well as from Losi RC.

Other than asking the team at MVRCA where we needed the Hammer Rey shipped to, we were given virtually no constraints or directions. This freedom allowed us to explore and modify the Hammer Rey to best suit our desert track and driving style. We were responsible for covering the cost of any parts or upgrades during the testing. |

It’s important to us that we only change what is needed to improve the Hammer Rey's performance or repair damage, and not to make changes based on what looks cool or shiny. Bling is not part of our agenda.

Now there is a part of me that wished Losi had used larger 1/8th scale components inside; I believe it would make the Hammer Rey much more robust, but it would have needed to be a completely redesigned around these larger elements. They would lose the ability to use parts from the Rock Rey and Baja Rey, and ultimately I could imaging the cost increasing to $700 or a $800 price range ( which I would also gladly pay). All of this wishful thinking aside, the Hammer Rey is a good looking and well-built RC platform for the $500 price tag.

Looking over the rest of the trophy Jeep, the fit and finish is good and on par with other Losi RC products. The suspension feels plush, and the scale details are a nice touch. When it comes to scale details, I’m not generally a fan of scale details – they just add unnecessary weight, but on the Hammer Rey they do look pretty sharp. For the time being I will leave some of them installed, but I already have my eye on pulling the spare tire.

Looking over the rest of the trophy Jeep, the fit and finish is good and on par with other Losi RC products. The suspension feels plush, and the scale details are a nice touch. When it comes to scale details, I’m not generally a fan of scale details – they just add unnecessary weight, but on the Hammer Rey they do look pretty sharp. For the time being I will leave some of them installed, but I already have my eye on pulling the spare tire.

|

When comparing the Hammer Rey’s differential to the 1/8 scale Nomad DB-8, it’s much smaller in size.

Same with the drive shaft diameters; the Hammer Rey’s drive shaft is noticeably thinner than what is found on a 1/8 scale buggy. This smaller scale of parts continues through the shocks and steering components, as well as hubs and steering spindles. |

When considering these parts, there is no question that the Hammer Rey is a 1/10 platform based on the size of parts underneath the body, and while it is for sure a long 1/10 machine, it’s a 1/10 machine none the less.

|

There are two color schemes offered on the Hammer Rey, and we lucked out with the green / grey / white color pattern which is our favorite. The Hammer Rey also comes in a more striking red and black combo, but it’s a bit dark for my taste.

The plastic body panels are well designed, fitting snug over the top of the cage. Like the Baja and Rock Rey's from Losi, there are 9573 screws securing the panels in place. We're kidding, there are a few dozen or so screws used to hold 4 different body panels in place. |

|

On the Scale

One of the first things I wanted to learn was the “dry” weight of the Hammer Rey, by placing it on the scale without a battery installed. It will be some time before I decide what 3s battery I will end up using, so for now a weight for just the truck is good starting point to establish. This way as changes are made, we can come back to the initial weight and see if there is a gain or loss, as well as a changing of the overall balance. It’s also a good way to track the weight changes with after-market parts. This also allows you to compare the weight of your truck to our setup, without battery weight skewing the data. With the SkyRC scale reading from each tire, the total weight comes in at 4544 grams, with a noticeable weight bias towards the rear of the truck; 43/57. We are going to work on losing some weight and shifting the weight bias a bit more forward. |

The OEM servo is the Spektrum S614S Metal Gear Servo to handle the steering needs, and while it seems to be a good choice out of the box, I’m planning on upgrading the servo as well as the electronics at some point during this project.

As part of the scale details to the Hammer Rey, there are a small sets of LED lights mounted under the headlights, on the front bumper, and on a light bar spanning the top of the driver’s cage.

Looking at the Hammer Rey in totality, this is a good quality set of electronics for any RTR package, and for the casual driver I feel they should hold up for some good use. Rather than hash out any more detail on the scale items, check out the new Losi RC website through this link: Losi RC

As part of the scale details to the Hammer Rey, there are a small sets of LED lights mounted under the headlights, on the front bumper, and on a light bar spanning the top of the driver’s cage.

Looking at the Hammer Rey in totality, this is a good quality set of electronics for any RTR package, and for the casual driver I feel they should hold up for some good use. Rather than hash out any more detail on the scale items, check out the new Losi RC website through this link: Losi RC

|

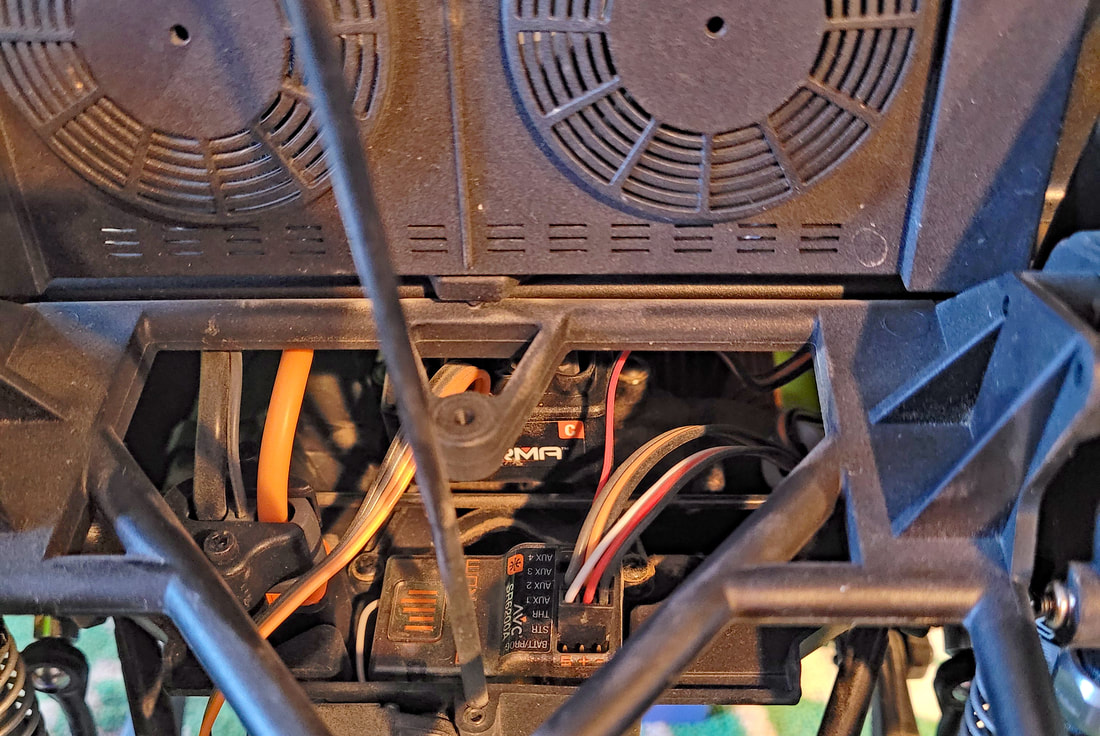

Electronics

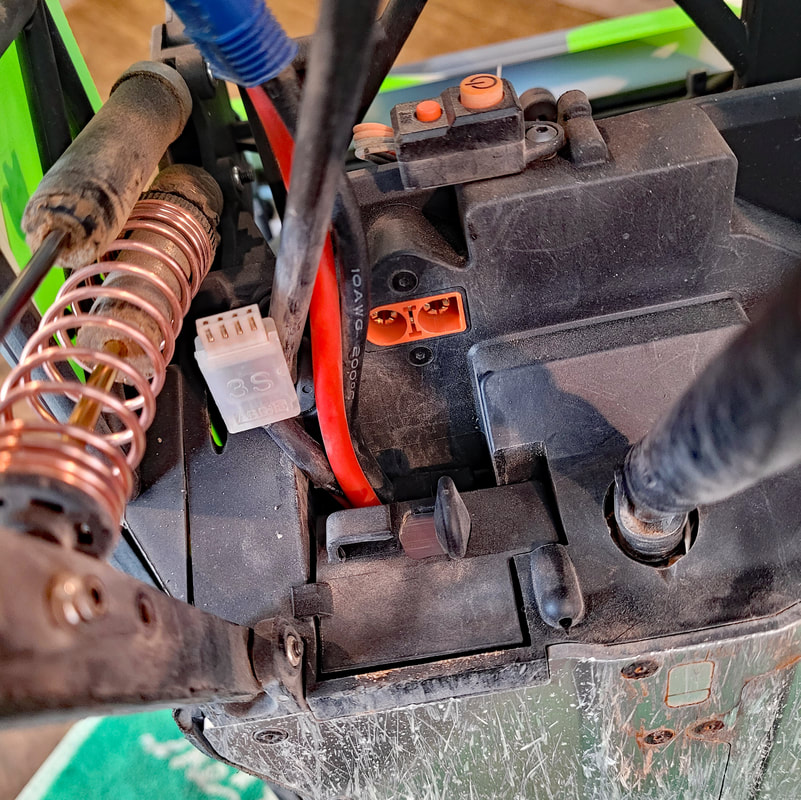

Under the umbrella of Horizon Hobbies, the Hammer Rey comes outfitted with a Spektrum 3150Kv brushless motor and 130A smart ESC with DX3 radio system. Overall, this is a decent setup and fairly standard for most Horizon products, but it is unsensored and gives a bit of the "coggy" startup racket when you get rolling. The 3150kv motor puts this well in the 3s category, with running a 2s battery as optional. I’m sure someone will run this on 4s, but I don’t expect much life from the parts on 4s. 3s is most likely the sweet spot for this setup. The motor is outfitted with a nifty aluminum heat-sink shroud which encases most of the motor can. |

Nitto Trail Grapplers

Staying with the trend of supplying high-quality tires on their RTR offerings, the Hammer Rey comes with an excellent set of Nitto Trail Grappler tires which are glued to a set of plastic KMC beadlock-styled 2.2 wheels.

The Nitto Trail Grappler is the very tire Casey Currie is running on his Trophy Jeep, which is the source and inspiration for the Hammer Rey.

Personally, I was quite pleased to see the Nitto tire on the Hammer Rey due to the immense amount of support and effort Nitto Tires has given to the Ultra 4 racing series as well as their crown jewel event; King of the Hammers. In the 1:1 world, Nitto is one of the most respected tire makers in the market, and their off-road designs are stellar.

Staying with the trend of supplying high-quality tires on their RTR offerings, the Hammer Rey comes with an excellent set of Nitto Trail Grappler tires which are glued to a set of plastic KMC beadlock-styled 2.2 wheels.

The Nitto Trail Grappler is the very tire Casey Currie is running on his Trophy Jeep, which is the source and inspiration for the Hammer Rey.

Personally, I was quite pleased to see the Nitto tire on the Hammer Rey due to the immense amount of support and effort Nitto Tires has given to the Ultra 4 racing series as well as their crown jewel event; King of the Hammers. In the 1:1 world, Nitto is one of the most respected tire makers in the market, and their off-road designs are stellar.

|

The rubber quality of this tire feels pliable but tough, something close to a medium softness similar to that of a Basher tire.

It’s a good choice for something as challenging as rock racing, and my guess is that a softer compound would have a much reduced tread-life. The carcass feels firm but is not belted, and on the inside is what feels to be a very firm open-cell tire foam. Adding to the sharp looks of the tire is a high level of scale-detail in the lettering and lug pattern. Losi nailed the scale aspect of this tire in that at first glance it looks just like the real thing. Much like the 1:1 version, the tread pattern is a non-directional reverse-mirror pattern. |

Unfortunately for us as of this writing, there are no plans to offer this tire unmounted – and for what it’s worth I feel that’s an oversight. Knowing how abrasive rock racing is on tires, and this being a true 2.2” tire, it lends itself to being reversible on the wheel, there by extending tire life and allowing an even amount of wear. With the tire glued to the wheel, you can only change direction of the tread, but you cannot flip the inner and outer sidewall orientation.

For rock racing, wheel and tire selection will play an interesting role in developing the performance of the Hammer Rey, as well as the longevity in terms of life span for the drivetrain and suspension components. My guess is that heavy wheels and tires will take their toll, and I’m also betting that the OEM wheels and tires will prove to be one of the best options on the market for optimal performance.

Nitto Trail Grappler Tire Specs

For rock racing, wheel and tire selection will play an interesting role in developing the performance of the Hammer Rey, as well as the longevity in terms of life span for the drivetrain and suspension components. My guess is that heavy wheels and tires will take their toll, and I’m also betting that the OEM wheels and tires will prove to be one of the best options on the market for optimal performance.

Nitto Trail Grappler Tire Specs

- Height: 142mm tall

- Width: 45mm

- Weight: 176 grams

|

With the trophy Jeep still shiny and new, we headed out to the local soccer field to check out the Hammer Rey’s handling characteristics before we hit the desert track.

This particular soccer field is a favorite of ours to drive due to very short and dry grass. The surface keeps the traction-rolling to a minimum by allowing the rear end of the Jeep to break free in the corners. As an added benefit, the short grass height doesn’t drag on the bottom of the chassis. |

By starting on the grass, if we end up taking a corner too hard and roll the Jeep, which was most likely going to happen, the grass keeps the damage to a minimum. We didn’t want to tear up the Jeep too much before our first photo session on the desert track.

I had a few Spektrum 3s 5000 mAh batteries in the rack which I selected for today, but later on I will end up switching to SMC Racing lipo batteries once we start fine-tuning the suspension for track conditions and running weight. The SMC batteries are lighter and pack a serious punch; it’s our standard lipo battery for most “go fast” platforms in the fleet.

With the first battery installed, we headed out across the field at a moderate speed with an eye on the Jeep’s tracking and suspension. Right away the steering felt a bit twitchy, and looking closer at the Jeep I noticed that the front tires were toed slightly inwards. I could feel it due to how quickly the Jeep would dive into the corners and oversteer. I dialed down the AVC completely, and still the Jeep felt twitchy. Unfortunately, the OEM parts are not adjustable, so I made a mental note to replace these with adjustable turnbuckles.

I had a few Spektrum 3s 5000 mAh batteries in the rack which I selected for today, but later on I will end up switching to SMC Racing lipo batteries once we start fine-tuning the suspension for track conditions and running weight. The SMC batteries are lighter and pack a serious punch; it’s our standard lipo battery for most “go fast” platforms in the fleet.

With the first battery installed, we headed out across the field at a moderate speed with an eye on the Jeep’s tracking and suspension. Right away the steering felt a bit twitchy, and looking closer at the Jeep I noticed that the front tires were toed slightly inwards. I could feel it due to how quickly the Jeep would dive into the corners and oversteer. I dialed down the AVC completely, and still the Jeep felt twitchy. Unfortunately, the OEM parts are not adjustable, so I made a mental note to replace these with adjustable turnbuckles.

|

Increasing the speed, the Hammer Rey felt stable and a bit top-heavy, but this wasn’t much of a surprise. I could feel the cage and spare tire tug at the top of the truck, causing it to lean into corners at moderate speed.

Anything in the upper range of the throttle, and the truck would catch a tire during a turn and tumble over. Losi states on their website that the motor will push the Hammer Rey “up to 40 mph”, and this seems about right from my observations. On the grass with some tire slip, the Hammer Rey felt it was in the mid 30 mph range. Traction from the Nitto Trail Grapplers was ideal in that there was enough grip to rapidly accelerate, but not so much that the Jeep would immediately traction roll when you make a turn. I also noticed that even at full speed, the tires didn’t balloon. |

By the time I finished the first battery, I had the handling sorted out on the Hammer Rey, so unless I dug into a corner too fast or stayed on the throttle early into the turn, it wasn’t very hard to drive clean lines.

Like any solid-axle platform, you have to drive them with a bit more care than independent suspension setups. What I did like was the ability to put power down as I exited the corners, and the long wheelbase made the Hammer Rey easy to drift and power out of these turns.

There is also noticeable torque-twist when you mash the throttle, and a real functioning sway bar on the back would most likely help that. The smaller internal sway bar seems to be a little undersized for the Hammer Rey’s size, but that’s just a first impression. It may feel quite different on the desert track.

The long wheelbase and long-travel rear trailing arms are well suited to keep the Hammer Rey running smooth over bumps at a relative high speed, but the Hammer Rey is noticeably slower in straight-line speed than most off-road offering on the market. That said, any more top-end speed and the Hammer Rey would be a bit difficult to control in the corners due to it's higher center of gravity. I feel that Losi dialed in the just right amount of speed for this machine.

In the 1:1 world speed does play a factor, especially with Casey Currie's Trophy Jeep’s ability to sustain an unusually high top-speed, allowing him to make up time on a large desert racecourses. In RC, we really don’t have such long straight-away sections where a high top-speed will help you close the gap or pull away during a race. If anything, on a proper desert racetrack for RC, chances are that high speeds will result in far more damage to the truck when smashing into rocks. When it comes to top-speed, the Hammer Rey is plenty fast for it’s intended use.

After draining two battery packs on the field, we headed back to the shop to trim some weight and adjust the front suspension and steering linkages.

Like any solid-axle platform, you have to drive them with a bit more care than independent suspension setups. What I did like was the ability to put power down as I exited the corners, and the long wheelbase made the Hammer Rey easy to drift and power out of these turns.

There is also noticeable torque-twist when you mash the throttle, and a real functioning sway bar on the back would most likely help that. The smaller internal sway bar seems to be a little undersized for the Hammer Rey’s size, but that’s just a first impression. It may feel quite different on the desert track.

The long wheelbase and long-travel rear trailing arms are well suited to keep the Hammer Rey running smooth over bumps at a relative high speed, but the Hammer Rey is noticeably slower in straight-line speed than most off-road offering on the market. That said, any more top-end speed and the Hammer Rey would be a bit difficult to control in the corners due to it's higher center of gravity. I feel that Losi dialed in the just right amount of speed for this machine.

In the 1:1 world speed does play a factor, especially with Casey Currie's Trophy Jeep’s ability to sustain an unusually high top-speed, allowing him to make up time on a large desert racecourses. In RC, we really don’t have such long straight-away sections where a high top-speed will help you close the gap or pull away during a race. If anything, on a proper desert racetrack for RC, chances are that high speeds will result in far more damage to the truck when smashing into rocks. When it comes to top-speed, the Hammer Rey is plenty fast for it’s intended use.

After draining two battery packs on the field, we headed back to the shop to trim some weight and adjust the front suspension and steering linkages.

|

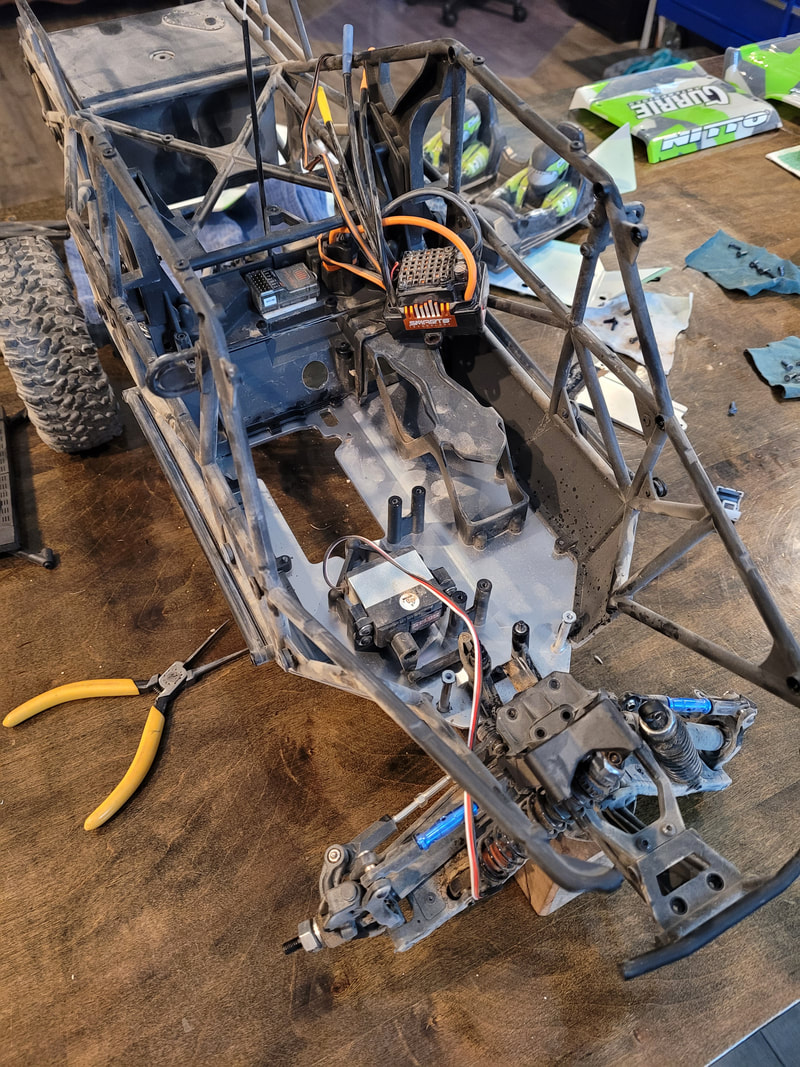

Back at the shop we had two specific items to address: center of gravity (COG) and front suspension setup. Of the two, we decided to start with lowering the COG by removing the spare tire in the back, as well as pulling many of the scale details.

We also removed the spare tire mounting hardware, the exhaust, bump stops, fake rear sway bar, fire extinguishers, and a few other small pieces. Initially we had thought to remove the rear fuel cell, but interestingly this plastic box does a great job in stabilizing the rear section of the chassis, so we opted to take the weight penalty and leave this on the truck. Next was the removal of scale parts mounting tabs molded into the rear chassis rails. These were trimmed away and then lightly polished. |

For the time being we decided to also leave the rear plastic fan housing behind the drivers and the lights on the roof, bumper, and head lights.

On the Hammer Rey, I find the lights attractive and they do a great job in bringing a “scale” look to the truck. After the first few photos sessions on the track, I might opt to remove them. I don’t drive at night, and again it’s just hauling extra weight. They also complicate working on the Jeep when servicing the center for front diff.

On the Hammer Rey, I find the lights attractive and they do a great job in bringing a “scale” look to the truck. After the first few photos sessions on the track, I might opt to remove them. I don’t drive at night, and again it’s just hauling extra weight. They also complicate working on the Jeep when servicing the center for front diff.

|

With the first pass of weight removal complete, it was time to address the front suspension setup. From the factory, Losi uses fixed-length camber and steering links, and while on paper these are most likely to be the correct lengths, in reality you almost always need adjustability in these parts.

This is why virtually every upper-end RC platform has turnbuckles and rod ends. This allows you to lengthen or shorten these links to set the desired camber and toe in/out for your needs. This Hammer Rey needed two specific changes; more camber to the front tires and more toe-out to settle down the steering. I searched around in the parts bin and found a set of GPM turnbuckles for the ARRMA Senton that were close enough to set the camber to a negative 2-degree inwards tilt. This will help dig the tire in on sharp corners and maintain a flat contact patch for the tread while turning. |

|

For the steering links, I used a set of Team Associated turnbuckles for the Nomad DB-8. I used the same rod ends from GPM, and these were just about perfect for the steering.

With these parts, I set a 1-degree toe-out for the front tires. This will help in cornering and remove the erratic feel of the Jeep's handling. For reference, the camber links are approximately 72.5mm eye to eye, and the steering links are approximately 90mm eye to eye. Keep in mind that these are approximate numbers; I don’t have a contact within Losi engineering to verify these measurements. That said, this is the beauty of adjustable turnbuckles; a few turns either way and you’re set. |

Now for a word on “upgraded” fixed-length camber and steering links; these are super dumb. I looked on Ebay and there are a number of these made from aluminum and called an upgrade, but they are doing nothing more than adding weight and giving you no ability to fine tune these settings. Here’s an insight on this topic; go check out any 1/8 buggy, Truggy, or SCT from any top company such as Tekno, X Ray, Kyosho, Serpent, HB, TLR, AE, or any others and you will not find a single fixed-length camber or steering link. None of them have this part as non-adjustable. You must be able to make adjustments in these key areas in order to properly set up your car. Don’t think these are just for racing platforms either, ARRMA uses them on every product from their EXB line, which are basically the ultimate Bashers on the market.

Plastic fixed links save on the price of the build for the manufacturer, and the plastic does bend / flex a bit to help absorb some of the punishment the Hammer Rey is surely going to experience. Switching these to rigid aluminum will only transfer this punishment to another part, which is probably more expensive to replace than a plastic link. Moral of the story; don’t buy a fixed camber or steering link made of any alloy, ever.

I did order additional turnbuckles and link ends to experiment with, and once I feel the most ideal combo is found, I will update this blog. For the time being, unless you have a decent bin of spare parts for link ends, pivot balls, and turnbuckles, you might want to swing by your local hobby shop to have access to any parts you may need. I reused the pivot balls from the Hammer Rey's link-ends so they would fit. Just keep that on your radar if you decide to make this change.

Plastic fixed links save on the price of the build for the manufacturer, and the plastic does bend / flex a bit to help absorb some of the punishment the Hammer Rey is surely going to experience. Switching these to rigid aluminum will only transfer this punishment to another part, which is probably more expensive to replace than a plastic link. Moral of the story; don’t buy a fixed camber or steering link made of any alloy, ever.

I did order additional turnbuckles and link ends to experiment with, and once I feel the most ideal combo is found, I will update this blog. For the time being, unless you have a decent bin of spare parts for link ends, pivot balls, and turnbuckles, you might want to swing by your local hobby shop to have access to any parts you may need. I reused the pivot balls from the Hammer Rey's link-ends so they would fit. Just keep that on your radar if you decide to make this change.

|

With the first round of the changes complete, back onto the scale for the Hammer Rey. The resulting numbers were quite pleasing; we dropped 321 grams resulting in a new weight of 4223 grams with a much-improved 47/53 split.

Keep in mind that we do not have a battery installed for these weights. We will get to that detail shortly. From here it was time to head out to the desert track for our first round of testing in real conditions. |

|

First Track Session

We headed out to the desert track to get our first taste of what the Hammer Rey was all about. The new desert track is modeled after the King of the Hammers desert racecourse, blending aspects of rock crawling, high-speed handling, and tight, winding turns in rocky and silty terrain. While the track is still undergoing a few final changes, it’s good to go for test laps and informal racing. During the track's development, we logged a number of laps with the Losi Lasernut U4 to fine-tune the track’s layout. |

I’m not going to get into too much detail about the track in this blog; there will be a separate section on the website dedicated to the track itself.

|

For these first few testing sessions we continued to use the Spektrum 3s 5000 mAh battery, but a new batch of SMC Racing batteries have been on order and should be arriving soon.

Installing the battery and rolling out from the pits, the Hammer Rey’s suspension was plush and stable, working smoothly over the rugged terrain. I’ve never been a fan of the AVC technology, so I turned that setting all the way down and proceeded to run a dozen or so laps. Overall the Jeep felt very good with the removed weight from the top and initial factory suspension setup. |

The Hammer Rey wasn’t leaning to the side excessively and the rear axle walked nicely around the tight corners. It’s not Lasernut nimble, but pretty good for it’s layout.

|

I could tell that the diffs were either partially full or running a very light oil for two reasons; first it actually cornered quite well and second, it frequently became stuck in the rock garden when I slowed down.

Either the front or rear tires would spin while the opposite sat idle; most likely the center differential being empty or light on oil. |

I made note of this and tried to carry a bit more speed through the rock garden, but the excellent cornering performance on the loose desert track actually made up for the inconvenience in the rock garden.

Increasing speed, I found that the rear end squatted a bit more than I cared for, striking the chassis on rocks heading down the main straight. On this track I would need to adjust the ride-height to cut down on some of the impacts.

Increasing speed, I found that the rear end squatted a bit more than I cared for, striking the chassis on rocks heading down the main straight. On this track I would need to adjust the ride-height to cut down on some of the impacts.

|

The front steering was about what I expected for a RTR servo and plastic steering linkage, and with the large rock strikes peppering the front tires, I was already planning on a servo upgrade.

As for power, the motor felt plenty strong, although I really wanted to install a sensored system sooner than later. The slow-speed cogging was noticeable in the rock garden and made me cringe a bit when weaving my way among the larger boulders. |

After draining the first pack, I let the truck cool off while I inspected it for any damage or parts out of position. Other than a few small rocks lodged here and there, nothing was amiss with the Hammer Rey.

I slid in a fresh battery and headed back out.

I slid in a fresh battery and headed back out.

|

As the laps increased in number, my comfort with the Hammer Rey also increased, giving me confidence to push it faster on the straights and dive deeper into the corners.

A few times I entered a corner a bit too hot and ended up rolling when I cut the wheels, but it was clearly driver error. Something else that was impressing me were the factory tires. These had a perfect amount of traction and suppleness for the track, softening some of the smaller bumps while still digging into the rock and maintaining control. |

It’s a shame that Losi doesn’t sell these as stand-alone tires, so I'm already thinking that at some point these Nitto tires are going to be removed from the factory plastic wheels and installed on a set of aluminum beadlock wheels.

I finished up the rest of the battery pack and called it a day. The summer weather out here in the desert puts a serious strain on the electronics, and typically I try to be done with any desert track racing by 10am.

I finished up the rest of the battery pack and called it a day. The summer weather out here in the desert puts a serious strain on the electronics, and typically I try to be done with any desert track racing by 10am.

|

After the first track session, we headed back to the shop to make a few changes.

First was to test out a change in shock oil to establish a baseline and make any adjustments needed from there. So far, the front had been handing the terrain very well with what felt like a lower weight oil, allowing the suspension to cycle quickly and absorb the difficult terrain. We pulled the front shocks, cleaned them of the old oil, greased the seals with Noleen SF-3 grease, then refilled with TLR 30 wt shock oil. |

For the rear we followed the same process, but selected 50 wt TRL oil to help slow down the rear shocks a bit. At times the rear end felt a touch jittery and blew through the travel a bit faster than I had wanted. My guess was to start with the 50 wt oil and adjust from there.

|

Gripe Time

As many of you know, working on the Rey series of trucks and buggies from Losi is a major pain in the rear. I’ve joked about half the Hammer Rey’s weight is located in the hundreds of screws holding the Jeep together, and you need to remove a fair number of them to access the center differential. I had hoped that Losi changed the layout to make accessing the interior easier, but this is not the case. Much like the Rock Rey and Baja Rey, the Hammer Rey is tedious to work on. |

I opted at this point to take the easy way out and leave the diffs for the time being. I was curious to see what the changes to the shocks would do out on the track.

|

Back on the track, the rear end of the truck felt much better, moving smoother through the bumps and choppy terrain, but the front was much too soft.

The front would quickly pack down in corners and then spring the front back up when I hit the throttle, often times breaking traction and causing some understeer. In a straight line the setup felt pretty good, but in any tight handling sections of the track caused me all kinds of grief. |

After a second battery pack on the track, I decided to do two things back at the shop; increase oil weight and the slightly raise the front ride height.

|

With the results of our last track session fresh in mind, we decided it was time to tear into the Hammer Rey and service the differentials as well as make a shock oil change in the front. As many of you are aware, working on any of the Rey series from Losi is a pain, and the Hammer Rey is no different.

After removing what seemed like nine thousand screws, we were finally able to remove the cage and get to the internals, and unfortunately that’s when our first bit of trouble started. With the transmission in hand, we could not remove the center differential out-drive driveshaft coupling. The screw was not hard to remove, but it seems the Loctite gremlins over-saturated this connection and the out-drive was stuck. After 30 minutes of applying heat from a soldering iron, I still could not get it to budge. With that in place, I could not remove the center diff from the plastic transmission housing. Mulling over my options, I decided it was reason enough to upgrade the transmission housing to aluminum and order a few extra differential bits and pieces. While I’m not a big fan of adding weight or random aluminum parts to any rock racer, upgrading the transmission housing is one of the few exceptions. I have found that aluminum supports the differential much better and holds up to repeated servicing over time. |

|

Knowing the replacement parts were a few days out, I reinstalled the center differential without service and rebuilt the front with 30k weight and 20k in the rear differential. The front differential is also not much fun to remove, but easier than the center differential.

Since I had the differential out for servicing, I wanted to show you how small the Hammer Rey differential is in comparison to the Nomad DB-8's differential. Keep in mind the Hammer Rey has a longer wheelbase, sits higher, and is overall a larger platform than the Nomad DB-8. |

Thus, while the Hammer Rey has a size advantage over the 1/8 scale Nomad, it is actually uses 1/10 scale drivetrain components.

|

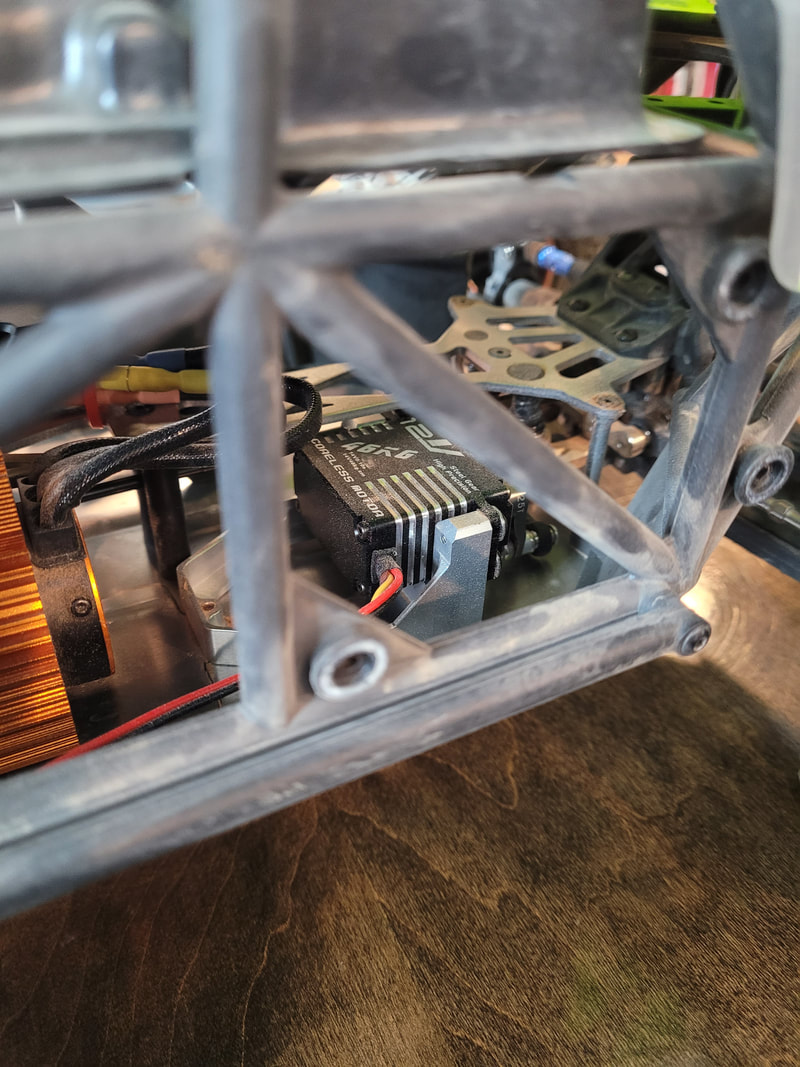

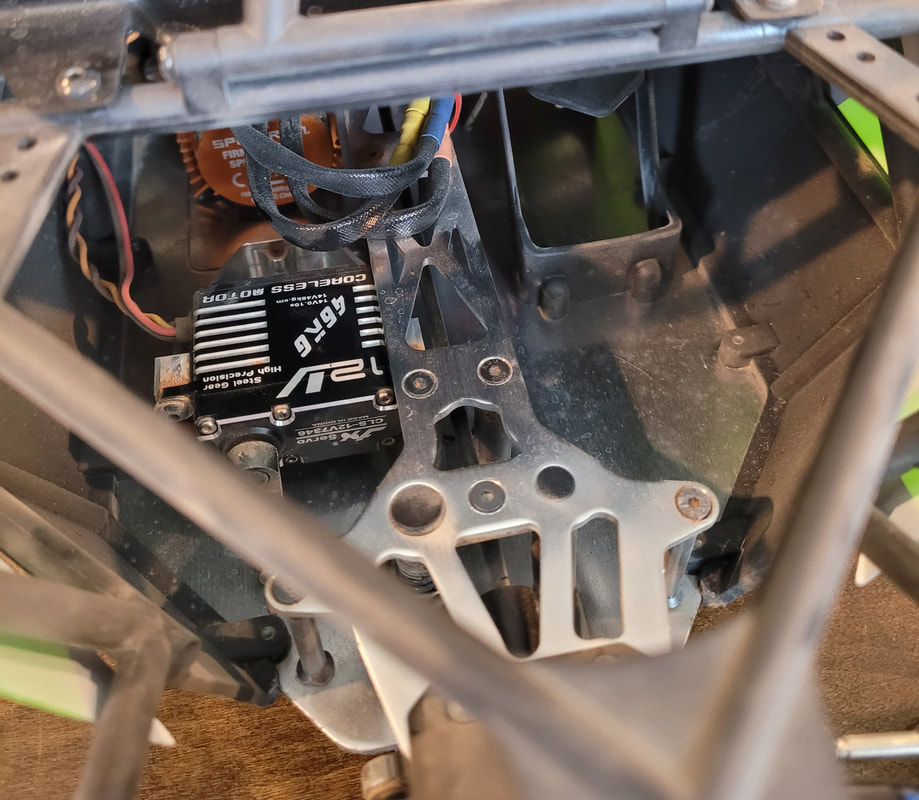

Two Months Later

Over the past few months we've spent several afternoons on the desert track, running through batteries and making small changes to the Hammer Rey’s suspension. The new aluminum housing for the center differential arrived from EBay, and with a bit more tuning and testing, we arrived at 50k being the ideal weight for the center differential. During this testing time, the OEM servo was fading fast, simply due to the extreme conditions of the rough desert track. The steering was slowing down and seemed unable to maintain direction under heavy load. To remedy this, I decided to roll the dice and try out an off-brand direct-power servo to see if it would handle the rough conditions. Along with a new servo, I purchased an aluminum servo mount and new aluminum servo steering linkage. It didn’t make any sense to upgrade the servo and leave the mount and linkage as plastic, allowing it to bend under the increased torque of the servo. |

Installing the new parts required wiring a pigtail for the servo’s power directly to the ESC’s cables. This way the servo will be powered at the moment the battery is plugged in. That was the easy part.

The trouble began in that I needed to rework the aluminum steering linkage from Vitavon Racing. It seems that Vitavon Racing released a set of steering linkages for the Hammer Rey which hadn’t been fully tested. It worked fine if you either drove straight or to the right, but the linkage would bottom out on the chassis if you tried to turn to the left. A little ( a lot ) of grinding, and I was able to have a Hammer Rey with a full range of steering.

Also during this time we removed the factory wheels and tires, and soaked off the rubber Nitto tires from the wheels using a sealed can of acetone and some patience. Once the tires were removed, we washed them with soap and water, then dried completely. Then they were coated with a layer of silicone oil and stored in an air-tight bag for later use.

With the Nitto tires in storage, we continued testing with a variety of 2.2 rock racing tires, making notes of what performed well and what seemed to struggle. More on that later.

The trouble began in that I needed to rework the aluminum steering linkage from Vitavon Racing. It seems that Vitavon Racing released a set of steering linkages for the Hammer Rey which hadn’t been fully tested. It worked fine if you either drove straight or to the right, but the linkage would bottom out on the chassis if you tried to turn to the left. A little ( a lot ) of grinding, and I was able to have a Hammer Rey with a full range of steering.

Also during this time we removed the factory wheels and tires, and soaked off the rubber Nitto tires from the wheels using a sealed can of acetone and some patience. Once the tires were removed, we washed them with soap and water, then dried completely. Then they were coated with a layer of silicone oil and stored in an air-tight bag for later use.

With the Nitto tires in storage, we continued testing with a variety of 2.2 rock racing tires, making notes of what performed well and what seemed to struggle. More on that later.

|

We also needed to change out the Spektrum receiver and bind into our DX5 Pro transmitter. In the past I’ve had problems with AVC and direct-power servos, so I side-step all of this by using a new two-channel receiver.

With new parts installed and a recalibration of the ESC as well as an end-point adjustment, we were ready to put everything back together. Hitting the track with the new steering setup installed, the Hammer Rey was much more composed and immediately showed a markedly improved level of performance. The steering was precise and plenty of traction was reaching all four tires. For the most part the Hammer Rey was proving to be a fun and enjoyable rock racer, capable of handling the harsh terrain and keeping things interesting behind the wheel. With the drivetrain figured out and the steering solved for the time being, the remaining work was tuning the the rear suspension. I needed to experiment more with shock oil weight and springs, but the complexity of removing the rear shocks for tuning and adjustments was aggravating. |

|

When working on the Hammer Rey, you must accept that you will need to remove the side panels to access the shock mounting screws, but what I find troubling is that the upper screws on the dampener and shock are covered by the roll cage.

This is aggravating because fine-tuning a rock racer requires frequent adjustments to the shock’s oil and springs, and having these screws obstructed is a vexing oversight. For a basher, this is probably not a big deal in that most people just pick a setting and never change it, but for those who are using the Hammer Rey for rock racing competition, it’s a stumble in the design. To access these screws, you need to remove most of the screws holding on the side cage assembly and bend it out of the way. This could have easily been designed around while developing this platform. |

|

After testing a few different spring setups on the OEM shock, I decided to switch to the Proline Racing Power Stroke XT 5” shocks.

These units had the right amount of travel and felt much more robust than the OEM shocks. Trouble was figuring out the right spring setup. I went through all the Proline spring options for this shock, but even the stiffest spring setup was still too soft and had the rear of the truck sagging low over the rougher sections of track. On a hunch I installed a set of Hot Racing ARRMA shock springs (ATF90PR148) and found the firm gold springs to be spot-on with 35cst oil and 25 cst in the dampener. To help protect the shocks and reduce some of the impact from sharp hits on the track, I installed a set of bump-stops on the shock piston rods. This particular set is from the Axial Ryft. |

|

Finally, there is the rear sway bar; it works, but it’s in a terrible spot.

The rear sway bar is tucked up high on the trailing arms with the cross bar running underneath the ESC, over the mounting bracket which holds down the center differential. To service the center differential, you have to pull the ESC and mount out of the way, and then twist / slide the mounting bracket from underneath the sway bar. Again, not a big deal for the basher, but highly aggravating for the driver who wants to tune their rock racer. That said, the factory sway bar does a pretty good job at controlling body roll. |

|

Luckily a few manufacturers noticed the “faux” sway bar on the Hammer Rey and opted to make a functioning unit which mounts in the same location.

Upon seeing this, I pulled the OEM sway bar off and installed one of the Vitavon Racing units. About 1 month after paying far too much for the Vitavon part, cheaper versions appeared on Ebay and look to be just as functional. This does not need to be a high-dollar part, so do yourself a favor and purchase a cheaper unit if you are inclined to make this change. So far from our testing on the track, it seems to be working well, but I caution that more testing would be needed to approve of its use in high-speed situations with the OEM unit removed. |

|

Additional Comments

With the past few months providing cooler weather and significant moisture coming in the form of rain and a bit of snow, track conditions have been about perfect, allowing us plenty of time for driving. Usually we run about three of our SMC Racing batteries through the Hammer Rey per session, using the first battery to get a feel for the track that particular day and then the second two for assessing performance. It been interesting to install different wheels and tires during this time, and its given us much to consider when picking the “right” tire for this track. |

An unexpected standout was a set of worn JConcepts 2.2” Scorpios we had left over from a few crawler projects. The lugs had been trimmed to allow more spacing in-between the remaining lugs, and these hooked up very well in the loose dirt and rock sections. Also surprising us was a set of Ebay knock-off BFG's which performed well beyond the $35 price for all four tires.

That said, there were quite a few tires which did very well on the track, and it seems that the Hammer Rey isn’t terribly picky as to what will run well.

That said, there were quite a few tires which did very well on the track, and it seems that the Hammer Rey isn’t terribly picky as to what will run well.

|

During this time, we continued to maintain and service the Hammer Rey, and eventually we needed to replace the rear axle housing due to wear and tear from the track. The bottom of the third member had worn through in some areas, allowing dirt to work its way into the ring and pinion gear.

We replaced the axle housing with a stock Losi unit, but added in the SSD aluminum third member ( SSD00177 ) for increased rigidity in this critical area. I wished the SSD unit was a thicker plastic housing, but they opted to go with machined aluminum, and it’s rather well made. I’m not a fan of the added weight, but it should hold up to the abuse. In the rear, the new Proline Racing shocks and Hot Racing springs have been doing well, and for the time being the front factory shocks are holding up to the abuse. I feel there is some room for improvement with the front shocks, but I haven’t quite figured out exactly what I’m looking to accomplish. I changed out the springs to a stiffer set I had on hand, but I can’t remember where I picked them up from. I think they might be Hot Racing springs. The new springs helped to maintain the ride height without giving up too much small-bump compliance. |

|

As for the rest of the Hammer Rey, the parts are holding up reasonably well, but the rod ends on the steering links have developed some play and the motor shudders terribly at low speed.

It shouldn’t come as a surprise that there is other wear and tear on the Hammer Rey, but I’m convinced the plastic parts on the truck have an inherent amount flexibility, playing a significant role in preventing catastrophic damage. The upgraded rear sway bar has been performing well and I’m pleased with the upgrade, but I can’t say that it’s functionally better than the OEM sway bar. With the new sway bar, it’s far easier to get to the center differential to make fluid adjustments, and it has a nifty scale look. |

This leads us into the topic of the center differential and how adjusting the fluid viscosity is critical for optimal performance, yet getting to the center differential is a giant pain in the rear. Unfortunately, there really is no good solution for this other than suffering through the ordeal of pulling everything apart to access the center differential.

I have read about some drivers locking up the center differential and just ignoring that tuning element, and while it does work, your handling characteristics are going to feel very twitchy and throttle sensitive. In short, it will be hard to drive the truck fast on a curvy, technical track. You’ll spin out frequently and it will suffer from excessive oversteer. We have been happy with 50k in the center differential for this track and it has proven to be a good middle ground for both the slow-speed rock garden and fast technical corners.

The steering servo has been doing well and seems to be holding up to the abuse, and the improved steering response has been helpful in guiding the Hammer Rey along the desert track. The upgraded mount and modified steering linkages also play a positive role with the steering.

I have read about some drivers locking up the center differential and just ignoring that tuning element, and while it does work, your handling characteristics are going to feel very twitchy and throttle sensitive. In short, it will be hard to drive the truck fast on a curvy, technical track. You’ll spin out frequently and it will suffer from excessive oversteer. We have been happy with 50k in the center differential for this track and it has proven to be a good middle ground for both the slow-speed rock garden and fast technical corners.

The steering servo has been doing well and seems to be holding up to the abuse, and the improved steering response has been helpful in guiding the Hammer Rey along the desert track. The upgraded mount and modified steering linkages also play a positive role with the steering.

|

Comments on the Truck

As much as we love the Hammer Rey, I think it’s best to start out by reviewing some of its deficiencies before we delve into the positive attributes. There are a couple of things to keep in mind as we start reviewing these details. First item to note is that during the course of this review, we didn’t spend any time doing burnouts in parking lots or mindless donuts in dirt fields, or the worst – jumping off dirt piles. |

I truly do not understand the fascination of jumping RC’s trucks and buggies off large mounds of dirt or even what can be learned from the practice, other than keeping companies like M2C Racing in business. The Hammer Rey is a rock racer by design, and it only made sense to focus our attention as to how it performed on an actual rock racing track.

|

Run Time

Over a period of 6 months of testing, we have logged 58 hours of driving on the desert track with a total of 127 3s lipo battery packs used. Yes, we keep a small notebook for each RC vehicle in the fleet, noting run time, battery pack consumption, service intervals, and performance notes. Our driving style was to move as quickly around the track as possible without subjecting the Hammer Rey to unnecessary abuse or damage. Rock racing is a game of attrition, and driving hell-bent for leather on this track will mostly likely prevent you from completing more than a dozen laps. That said, we took some nasty hits during testing but overall the Hammer Rey held up surprisingly well. |

Things We Immensely Dislike

|

Roll Cage / Chassis Setup

The Rey series have been a mainstay in the Losi off-road lineup for over five years, and by now I feel they should have addressed the challenges which the current roll cage and chassis setup creates for service and maintenance. The original 1/10 Rock Rey enjoyed wide-spread popularity for some time, but many owners complained about working on the platform in that it required a nearly complete disassembly of the cage to access the center differential and drivetrain. I can’t imagine that Losi was not aware of this widespread dissatisfaction. I read plenty of instances where owners reduced their driving time with their Rey platforms just to avoid the maintenance requirement, with a few opting to sell them off because they were such a pain to work on. |

With this well-known deficiency, I’m disappointed that Losi hasn’t redesigned the cage to be a removable piece or at least something that can pivot or be lifted out of the way, similar to the Lasernut U4, or better yet like the Nomad DB-8 was setup with its robust body posts and four large cotter pins.

Just recently Losi released their new desert buggy, the RZR Rey, and it does step away from the traditional Rey layout by offering a removable body and top-loaded battery tray. It may be that Losi was already addressing the cage and battery loading issue, but the Hammer Rey was already developed and released prior to the RZR Rey program. It’s just speculation on my part, but seems like a reasonable assumption.

So, with the release of the RZR Rey, it might just be that Losi has finally put this design aggravation of the Hammer Rey in the past.

Just recently Losi released their new desert buggy, the RZR Rey, and it does step away from the traditional Rey layout by offering a removable body and top-loaded battery tray. It may be that Losi was already addressing the cage and battery loading issue, but the Hammer Rey was already developed and released prior to the RZR Rey program. It’s just speculation on my part, but seems like a reasonable assumption.

So, with the release of the RZR Rey, it might just be that Losi has finally put this design aggravation of the Hammer Rey in the past.

|

Battery Loading

Battery loading from the rear is a necessary evil due to the Hammer Rey’s cage design, and it’s long overdue that this gets sorted out along with the chassis. This current setup requires you to use a battery which is set up with the power and balance cables oriented in the corner on the far side of the battery. With any other cable layout and you will not be able to use the battery of your choice. I find this aggravating because experimenting with battery weight and capacity is another aspect of a rock racer’s setup. I believe if they changed the cage design to be similar to the Lasernut U4, then the battery could be loaded from the top and eliminate the rear installation setup currently featured. Luckily, we were able to use a few of our light-weight SMC Racing 3s batteries from their V2 Extreme series, and place foam pads on the sides to keep them centered in the battery slot. |

Center Chassis Brace

This long strap of aluminum is buried deep within the Rey and requires its removal if you want to access the center differential or front bulkhead. This should be a sectional piece, much like the version GPM offers for the Lasernut U4.

Usually, GPM products are not at the top of my go-to list for upgrades, but they got this part right on the Lasernut and I hope to see one for the Hammer Rey soon. It would greatly simplify maintenance.

This long strap of aluminum is buried deep within the Rey and requires its removal if you want to access the center differential or front bulkhead. This should be a sectional piece, much like the version GPM offers for the Lasernut U4.

Usually, GPM products are not at the top of my go-to list for upgrades, but they got this part right on the Lasernut and I hope to see one for the Hammer Rey soon. It would greatly simplify maintenance.

Things we are neutral on

|

Electronics

Over the first year, the motor and ESC performed relatively well, but there was just a bit of cogging present when doing any low-speed rock crawling. This cogging only presented itself as an issue when we were navigating the chunky section of our rock garden on the desert track. At speed, the electronics have been adequate with a fair amount of power generated by the motor, but any more power either from a 4s battery or stronger motor would most likely damage the drivetrain components. |

By the end of our testing, the motor and ESC were on their last legs. A tremendous amount to cogging is now present with a nasty tremor running through the Rey at low speeds, but I’m not going to place all the fault on the electronics. Much of the blame is due to the rigors of rock racing, specifically the amount of dust and debris blowing through the vehicles as they race around the track.

As for the servo, well, it’s an RTR servo, so if you’re going to race, you already know that it will need replacement. No big surprise there. Just cruising around the dirt lot or casual bashing, it seems to be fine. When you do replace the servo, select a strong unit because the large 2.2 tires in rocky terrain will require some respectable power to turn the wheels. It’s worth upgrading to an aluminum servo mount at the same time. The thin plastic servo mount will twist under the increased load of a more powerful servo. There also might be some merit to installing a servo saver to help protect the servo.

As for the servo, well, it’s an RTR servo, so if you’re going to race, you already know that it will need replacement. No big surprise there. Just cruising around the dirt lot or casual bashing, it seems to be fine. When you do replace the servo, select a strong unit because the large 2.2 tires in rocky terrain will require some respectable power to turn the wheels. It’s worth upgrading to an aluminum servo mount at the same time. The thin plastic servo mount will twist under the increased load of a more powerful servo. There also might be some merit to installing a servo saver to help protect the servo.

Things We Love

|

Driving Style

When it comes to ripping laps around the desert track, I absolutely love the way the Hammer Rey drives. That said, the Hammer Rey is a platform which you need to pay close attention to while driving. Unlike the Lasernut U4 which nearly drives itself, the Hammer Rey is not a throttle-masher wide-stance / low CG rock racer. The solid rear axle and higher CG demands that you come off the throttle and pick specific lines when entering the corners, or risk upsetting the Rey and sending it into a cartwheel due to traction-roll. |

|

Most solid rear-axle platforms have this trait to some extent, so adjusting your driving style to mitigate traction-rolling is just part of the game. I also found running a little bit of drag brake helps settle down the truck when you lift on the throttle.

If you opt to keep the full suite of scale details on the truck, you will need to be even more conservative in the corners to prevent traction roll. With our layout, I rarely turn the truck on its side when buzzing through the corners. That said, jumping the truck is still a tricky endeavor on our track; it doesn’t take much of a mistake to end up sideways flying through the air. |

|

Looks

Like the Rock Rey and Baja Rey, Losi nails the look on the Hammer Rey with an excellent attention to the scale details of this truck. Knowing that scale detail is a big selling feature in today’s market, I believe many customers will appreciate Losi’s efforts to closely replicate Currie Enterprises’ trophy Jeep. Personally, I’m more of a Bronco guy, but the Hammer Rey does looks sharp. For those who want to shave weight and lower CG, most of these scale features are easily removable. And for those who wish to add more scale detail, there are plenty of parts floating around on Ebay to bedazzle your Hammer Rey. |

|

Tires

The Nitto Trail Grapplers are an excellent feature of the Hammer Rey, performing surprisingly well with the factory foams and plastic wheels. Losi seems to get this right on a fair number of their platforms, so I wasn’t shocked to see such a good set of tires from the factory. To further enhance the Trail Grapplers’ performance, we pulled the tires from the plastic wheels and remounted them on true beadlock wheels with proper CI Deuce's Wild closed-cell foams. With the change of wheels and foams, the Hammer Rey can really dig into the corners without folding the tire over the wheel. This improved handling in the tight corners and made it a bit nimbler on the treacherous straight-away of our desert track. |

The one deficiency of the tire is that the tight lug pattern can be overwhelmed by the motor’s torque. If you smash the throttle, the tires will spin a good bit before they hook up. Much like the 1:1 version, the traction is excellent when you apply power in a measured, controlled fashion. They do not have the traction of a more open lug design, like the VooDoo KLR’s, but the KLR’s style isn't used in 1:1 desert racing that the Hammer Rey is built for, thus it does not match the scale aspect. This doesn’t diminish the enjoyment of the Hammer Rey, but if fast lap times are your only goal, there are faster 2.2" tires to choose from.

|

Open-Wheel Layout

With the open-wheel layout of the Hammer Rey, testing tires is relatively simple because you don’t need to worry about tucking the tires under a full truck body. Beadlock wheels with extended SLW hubs are the way to go rather than axle extensions. Another bonus is that with so many 2.2” crawler tires on the market, there are many different options to experiment with. I’m sure there is even an optimal tire for dirt pile jumping or parking-lot donuts if that’s your thing. |

|

Current Status

With the testing complete for this review, I wanted to do a short look at the current condition of the Hammer Rey. Keep in mind that it’s seen more than a few laps on our U4 desert racetrack, taking a serious amount of punishment throughout the course of testing.

|

|

Final Thoughts

The Losi Hammer Rey has given us much to think about in the realm of rock racing platforms to choose from, and I believe it’s mostly due to one important factor: driver commitment. If you are not willing to commit to the tuning and maintenance process needed to fully develop and support the Hammer Rey, then most likely this RC platform will never reach its full potential. Knowing the inherent difficulty of working on the Hammer Rey, it should be considered before investing in this platform. I would also venture to say the Hammer Rey is better suited to more experienced RC drivers. |

|

That said, solid rear-axle rock racers offer a unique feel on the track, providing a much more realistic experience for the driver, forcing them to deal with the Hammer Rey’s limitations while exploiting its advantages.

The suspension setup and higher center of gravity, as well as the tendency of solid rear-axles wanting to roll makes this a harder platform to drive well when compared to the Lasernut U4. On the other side of the argument, this truly is a driver’s rock racer, rewarding those who put the time into mastering the unique traits of the Hammer Rey. |

The Hammer Rey is not the fastest nor most robust of all the rock racers in our fleet, but when it comes to delivering a truly engaging rock racing experience on the desert track, the Hammer Rey is about as good as it gets.

In closing, I want to thank my good friend Oscar T. Without his support, encouragement, and willingness to lend hours on the phone helping me sift through endless questions about rock racing, much of this project would not have been possible. For that, I'm truly thankful.

s.

s.