Team associated nomad db - 8

Nomad DB-8 Desert Racing Machine

Nomad DB-8 Desert Racing Machine

As the 1/8th scale Nomad Desert Buggy (DB-8) came coasting into the pits after draining the last battery pack remaining, I felt at that point there really wasn’t anything left for me to consider about this desert buggy.

It had been a long seven-month testing schedule comprised of nearly 100 different testing sessions and almost 300 battery packs through the now well-worn desert buggy.

While placing the Nomad DB-8 on the tailgate of the truck and unclipping the body, I could feel the heat radiating from the entire vehicle. It was another hot 95 degree summer morning at our outdoor desert racing course, and the battery felt like a Hot Pocket as I unhooked it from the connector. I powered up one of the small portable fans and perched it on the rear bumper, blowing air across the motor and ESC.

Worn, scratched, and running on its second set of tires, I felt the Nomad had shown every bit of performance it was capable of. That final battery pack brought an end to our testing schedule; this desert buggy held no more secrets. I admired the Nomad and it had come to hold the “top spot” in my RC collection.

It had been a long seven-month testing schedule comprised of nearly 100 different testing sessions and almost 300 battery packs through the now well-worn desert buggy.

While placing the Nomad DB-8 on the tailgate of the truck and unclipping the body, I could feel the heat radiating from the entire vehicle. It was another hot 95 degree summer morning at our outdoor desert racing course, and the battery felt like a Hot Pocket as I unhooked it from the connector. I powered up one of the small portable fans and perched it on the rear bumper, blowing air across the motor and ESC.

Worn, scratched, and running on its second set of tires, I felt the Nomad had shown every bit of performance it was capable of. That final battery pack brought an end to our testing schedule; this desert buggy held no more secrets. I admired the Nomad and it had come to hold the “top spot” in my RC collection.

Nomad DB-8 ripping through the short grass.

Nomad DB-8 ripping through the short grass.

For seven months I pushed the Nomad relentlessly over a myriad of terrains, with the testing schedule kicking off at the tail end of our mild winter and coming to a close during record breaking summer temperatures.

The following article is long and detailed look at the Nomad DB-8 from Team Associated.

It’s my hope that the following information will leave you with a complete and solid understanding of what the Nomad has to offer, clearly defining its strengths and its weaknesses.

But before we can talk about what it can do, let’s talk about what it is.

The following article is long and detailed look at the Nomad DB-8 from Team Associated.

It’s my hope that the following information will leave you with a complete and solid understanding of what the Nomad has to offer, clearly defining its strengths and its weaknesses.

But before we can talk about what it can do, let’s talk about what it is.

What is the Nomad DB-8?

Nomad DB-8's Natural Environment

Nomad DB-8's Natural Environment

Released in June of 2017, the Nomad DB-8 is a ready-to-run ( RTR ) 1/8th scale, four-wheel drive off-road desert buggy from Team Associated.

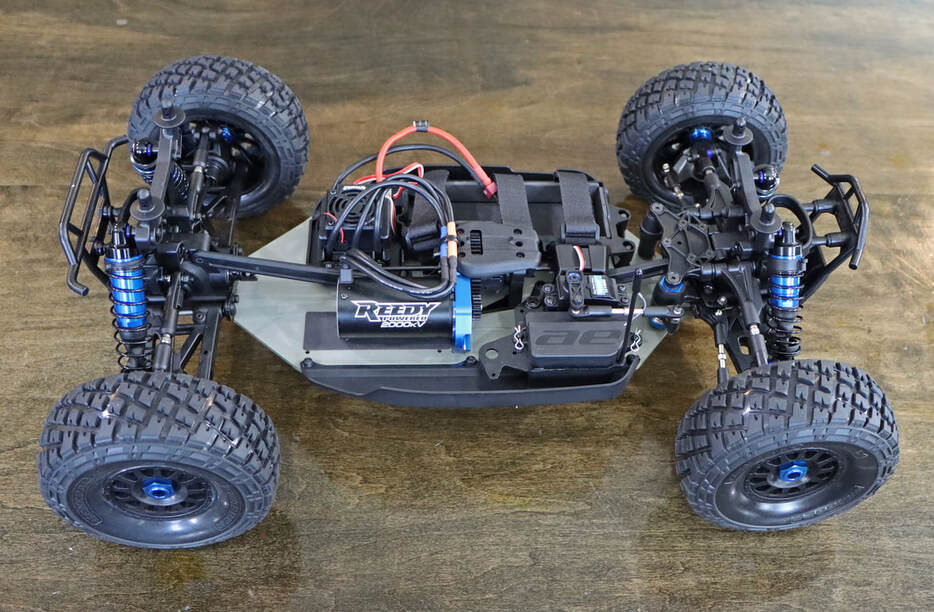

Based on a blend of parts from the RC8.2 Buggy and Truggy line of vehicles, the Nomad features a long-travel independent suspension, aluminum chassis, unique body and roll cage, and large off-road tires.

Designed to run 4s lipo batteries, the Nomad is a fast and robust desert machine.

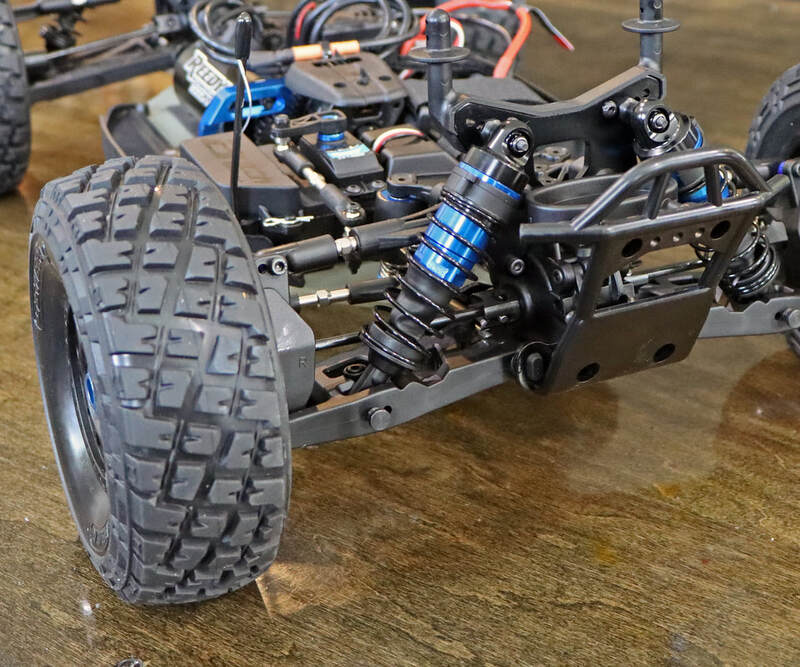

To handle the off-road rocks and bumps, the Nomad uses aluminum 16mm coil-over shocks which come with spacers (pre-load inserts) to adjust ride height. The open-wheel design allows for the use of large off-road tires and helps keep debris out from the inside of the buggy.

The Nomad’s wide aluminum chassis features an organized and open layout with the major electrical components evenly spaced for balance and accessibility. Unlike many brands which shoehorn-in the components, the Nomad’s wide 1/8th scale chassis places the servo and motor on the right side of the drivetrain and the battery and ESC on the left side. Wisely, the ESC is placed behind the battery at the rear of the chassis, preventing it from filling with dirt and debris kicked up by the front tires.

Based on a blend of parts from the RC8.2 Buggy and Truggy line of vehicles, the Nomad features a long-travel independent suspension, aluminum chassis, unique body and roll cage, and large off-road tires.

Designed to run 4s lipo batteries, the Nomad is a fast and robust desert machine.

To handle the off-road rocks and bumps, the Nomad uses aluminum 16mm coil-over shocks which come with spacers (pre-load inserts) to adjust ride height. The open-wheel design allows for the use of large off-road tires and helps keep debris out from the inside of the buggy.

The Nomad’s wide aluminum chassis features an organized and open layout with the major electrical components evenly spaced for balance and accessibility. Unlike many brands which shoehorn-in the components, the Nomad’s wide 1/8th scale chassis places the servo and motor on the right side of the drivetrain and the battery and ESC on the left side. Wisely, the ESC is placed behind the battery at the rear of the chassis, preventing it from filling with dirt and debris kicked up by the front tires.

Nomad DB-8's excellent chassis layout.

Nomad DB-8's excellent chassis layout.

This smart layout leaves plenty of room around the motor and ESC for passive cooling, as well as making pinion changes and differential servicing easy.

Another benefit to this open layout is that you can visually check the driveshaft and steering linkage conditions, easily spotting any damage or wear to the drivetrain.

With the open space inside the chassis, it’s also less likely to have pieces of gravel or rock to become wedged into a bad spot and cause damage.

Most rocks and debris kicked up into the chassis tend to vibrate to the rear and fall out the back or drop down through the clearance hole underneath the spur gear. Anything stuck in the chassis is easy to spot and remove.

The front and rear A-arms are massive, steering linkage robust, and the adjustable camber links are solidly built. You can see the RC8.2 racing buggy pedigree in the Nomad with many of the parts being the same between the two buggies. While not as radical in tuning options as a modern racing buggy, there are still plenty of adjustments for suspension setup.

Another benefit to this open layout is that you can visually check the driveshaft and steering linkage conditions, easily spotting any damage or wear to the drivetrain.

With the open space inside the chassis, it’s also less likely to have pieces of gravel or rock to become wedged into a bad spot and cause damage.

Most rocks and debris kicked up into the chassis tend to vibrate to the rear and fall out the back or drop down through the clearance hole underneath the spur gear. Anything stuck in the chassis is easy to spot and remove.

The front and rear A-arms are massive, steering linkage robust, and the adjustable camber links are solidly built. You can see the RC8.2 racing buggy pedigree in the Nomad with many of the parts being the same between the two buggies. While not as radical in tuning options as a modern racing buggy, there are still plenty of adjustments for suspension setup.

Nomad DB-8 Details

Nomad DB-8 Details

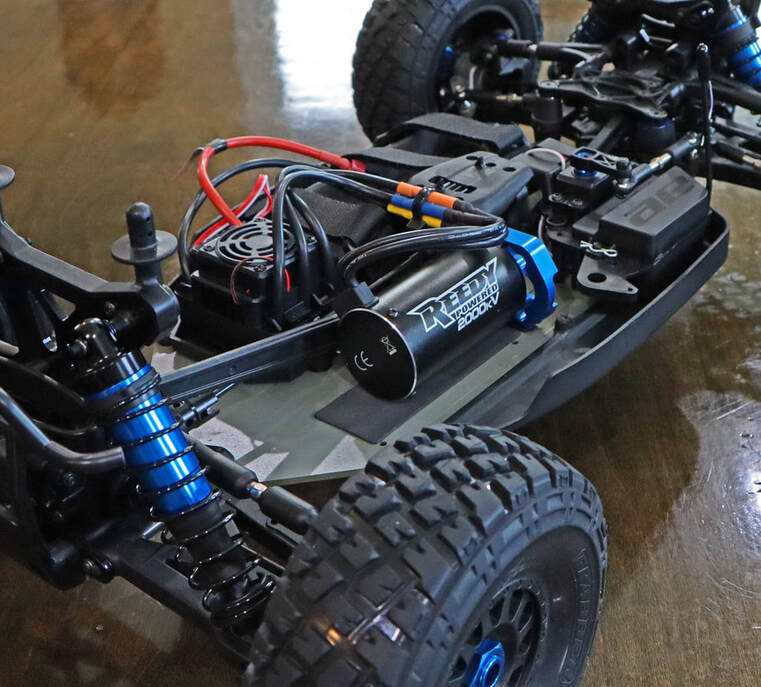

Transferring power from the 2000 kV Reedy motor are three easily accessible metal-geared differential housing. The main driveshafts coming off the center differential are standard dog bones with phased 3 x 12mm pins.

The rear driveshafts coming from the differential to the hubs are of the same design, but the front driveshafts turning the wheels use a dog bone and CVA combination.

The front and rear differentials use a 46/10 spiral cut gear and pinion, but at some point the replacement became a 46/10 straight cut gear and pinion. The center differential uses a 46 tooth plastic spur gear. The manual states that 20k differential oil is used in all three differentials.

The plastic roll cage is well constructed and features a series of body panels with colored stickers and graphics. Two drivers are in the cockpit and have some detail to their helmets and instrument panels. Securing the body and cage to the chassis are four large R-clips.

The rear driveshafts coming from the differential to the hubs are of the same design, but the front driveshafts turning the wheels use a dog bone and CVA combination.

The front and rear differentials use a 46/10 spiral cut gear and pinion, but at some point the replacement became a 46/10 straight cut gear and pinion. The center differential uses a 46 tooth plastic spur gear. The manual states that 20k differential oil is used in all three differentials.

The plastic roll cage is well constructed and features a series of body panels with colored stickers and graphics. Two drivers are in the cockpit and have some detail to their helmets and instrument panels. Securing the body and cage to the chassis are four large R-clips.

General Tire's Grabber Off-Road Buggy Tire

General Tire's Grabber Off-Road Buggy Tire

Planting the Nomad to the ground is a set of soft General Tire (GT) Grabber tires mounted on 2.2 / 3.0” plastic wheels. The tread pattern is scale in appearance, looking to be a mildly aggressive off-road type, but smooth enough to run at high speed.

The cleats are wide and offer a good contact patch with the ground. Looking closer at the cleats, you can see that they are slightly rounded on the edges with a finishing bead. Running down the sides of the tires are a blended series of cleats, beveled to transition smoothly into the tire’s sidewall.

It’s interesting to note that General Tire’s license for RC tires seems to be exclusive with Associated Electronics. There are no other RC companies that I’m aware of using the General Tire product, and only a few tires in production for Associated Electronics.

Inside the tire is a soft, single-stage foam suitable for most off-road conditions. After inspecting all four tires, I did not find any flaws in the tire mounting glue.

Like many 1/8th scale buggies, the plastic wheel uses a 17mm hex and 12.5mm pass-through hole.

There is also a conservative 8mm positive offset to the wheel. Standing 138mm tall and 52mm wide, the wheel and tire combination is similar to a truggy tire in height, thus lifting the chassis bottom higher off the ground than would a traditional 1/8th scale buggy tire.

The cleats are wide and offer a good contact patch with the ground. Looking closer at the cleats, you can see that they are slightly rounded on the edges with a finishing bead. Running down the sides of the tires are a blended series of cleats, beveled to transition smoothly into the tire’s sidewall.

It’s interesting to note that General Tire’s license for RC tires seems to be exclusive with Associated Electronics. There are no other RC companies that I’m aware of using the General Tire product, and only a few tires in production for Associated Electronics.

Inside the tire is a soft, single-stage foam suitable for most off-road conditions. After inspecting all four tires, I did not find any flaws in the tire mounting glue.

Like many 1/8th scale buggies, the plastic wheel uses a 17mm hex and 12.5mm pass-through hole.

There is also a conservative 8mm positive offset to the wheel. Standing 138mm tall and 52mm wide, the wheel and tire combination is similar to a truggy tire in height, thus lifting the chassis bottom higher off the ground than would a traditional 1/8th scale buggy tire.

Nomad's robust suspension setup from the RC8.2 racing buggy line.

Nomad's robust suspension setup from the RC8.2 racing buggy line.

Unlike wide truggy wheels, the Nomad uses a much narrower wheel and tire setup. Combined with the extended wheel hub, this creates a wide wheel base with plenty of steering travel for tight corners on technical terrain, but a lower rotational mass to overcome when accelerating.

The narrower wheel and 8mm positive offset moved the center contact patch inside the hub, giving a crisp feel to the handling and minimal scrubbing affect in tight corners.

Powering the Nomad is a Reedy 1515-SL 2000 kV brushless motor and SC1000-BL 1:8 ESC. This is a nice setup for any RTR and provides snappy acceleration on 4s with the OEM 15 tooth Mod 1 pinion gear. The power delivery is smooth for a non-sensored motor.

Keeping the Nomad pointed in the right direction is a Reedy 1514 MG digital servo with a 25 tooth spline and 15.0 kg-cm on 7.4 volts. It’s nothing spectacular, a bit on the slow side, but the mounting is solid and offers plenty of power to steer the wheels.

The narrower wheel and 8mm positive offset moved the center contact patch inside the hub, giving a crisp feel to the handling and minimal scrubbing affect in tight corners.

Powering the Nomad is a Reedy 1515-SL 2000 kV brushless motor and SC1000-BL 1:8 ESC. This is a nice setup for any RTR and provides snappy acceleration on 4s with the OEM 15 tooth Mod 1 pinion gear. The power delivery is smooth for a non-sensored motor.

Keeping the Nomad pointed in the right direction is a Reedy 1514 MG digital servo with a 25 tooth spline and 15.0 kg-cm on 7.4 volts. It’s nothing spectacular, a bit on the slow side, but the mounting is solid and offers plenty of power to steer the wheels.

Nomad DB-8 Green Color Scheme

Nomad DB-8 Green Color Scheme

There are two color options for the Nomad; a desert tan scheme and a dark green scheme.

The green shows off bolder colors, but I think the desert tan matches better with the black of the wheels and tires.

The Nomad comes standard with a XP-120 transmitter, but there is also a package version which includes a 4s lipo battery and charger.

The Nomad alone retails around $500 and the package version with charger and lipo battery is around $600.

Like most RTR’s, it comes fully assembled and ready to roll. In the box with the Nomad are a few basic tools, shock body spacers to adjust ride height, an excellent instruction manual, and transmitter. The ESC comes wired for T-Plug battery connectors. I use IC5 for all of my batteries, so right away I clipped the battery connector and soldered on a new IC5 plug.

The green shows off bolder colors, but I think the desert tan matches better with the black of the wheels and tires.

The Nomad comes standard with a XP-120 transmitter, but there is also a package version which includes a 4s lipo battery and charger.

The Nomad alone retails around $500 and the package version with charger and lipo battery is around $600.

Like most RTR’s, it comes fully assembled and ready to roll. In the box with the Nomad are a few basic tools, shock body spacers to adjust ride height, an excellent instruction manual, and transmitter. The ESC comes wired for T-Plug battery connectors. I use IC5 for all of my batteries, so right away I clipped the battery connector and soldered on a new IC5 plug.

What is the Nomad’s Role?

Nomad DB-8 is perfectly suited for desert conditions.

Nomad DB-8 is perfectly suited for desert conditions.

The Nomad, like most desert buggies, is one of those platforms which does just about everything pretty well, but it’s not a specialist in any particular field.

I’ve always felt that desert buggies were an under represented section of the market, but there are some understandable reasons for this situation.

To start, outside of the unfortunately small but interesting niche of rock racing, there are no real competitive racing events for desert buggies.

Most modern desert buggies have some design elements derived from U4RC Rock Racing, but they are not as purely focused on rock racing such as the Losi Rock Rey or Axial Bomber. Unlike the solid rear axles found on the aforementioned platforms, the Nomad’s fully independent suspension is from the 1/8th scale buggy racing side, giving it excellent stability and control at higher speeds.

Unfortunately this comes at a cost on large rock and slower technical terrain. While it does sit higher than a 1/8th scale track buggy, it does not have the ample amount of ground clearance a dedicated rock racer. Smashing thought large technical rock, the Nomad’s chassis is going to take a beating.

During its initial release, many drivers looked to use the Nomad for rock racing, but the wide chassis and shorter suspension travel (when compared to a solid-rear axle platform) didn’t perform as well on the large rockier sections of the tracks. Drivers were getting high-centered in some of the more tricky rock sections, making for slower lap times.

I’ve always felt that desert buggies were an under represented section of the market, but there are some understandable reasons for this situation.

To start, outside of the unfortunately small but interesting niche of rock racing, there are no real competitive racing events for desert buggies.

Most modern desert buggies have some design elements derived from U4RC Rock Racing, but they are not as purely focused on rock racing such as the Losi Rock Rey or Axial Bomber. Unlike the solid rear axles found on the aforementioned platforms, the Nomad’s fully independent suspension is from the 1/8th scale buggy racing side, giving it excellent stability and control at higher speeds.

Unfortunately this comes at a cost on large rock and slower technical terrain. While it does sit higher than a 1/8th scale track buggy, it does not have the ample amount of ground clearance a dedicated rock racer. Smashing thought large technical rock, the Nomad’s chassis is going to take a beating.

During its initial release, many drivers looked to use the Nomad for rock racing, but the wide chassis and shorter suspension travel (when compared to a solid-rear axle platform) didn’t perform as well on the large rockier sections of the tracks. Drivers were getting high-centered in some of the more tricky rock sections, making for slower lap times.

Nomad DB-8 getting some air at the local park.

Nomad DB-8 getting some air at the local park.

Keep in mind that while the Nomad uses 17mm hex hubs like most 1/8 buggies, popular wheels like Vanquish 2.2 wheels are designed for 12mm hubs and will not work on the Nomad.

Unless you’re willing to spend nearly $250 for custom aluminum beadlock wheels with 17mm hubs from a company like Motoworx, you’re stuck running plastic wheels and glued tires. This is unfortunately because there are some excellent U4 racing tires out there on the market.

That said, out in open desert spaces, the Nomad easily devours dedicated rock racers with superior handling and a solid top-end speed of approximately 40 mph with the 15 tooth pinion gear. In anything but the chunkiest of technical terrain, the Nomad is going to have the advantage.

On the other side of the spectrum, the Nomad is too heavy and slow to keep up with any dedicated 1/8th scale track buggy. The suspension would need to be completely reworked and the body changed, and by then you might just as well get a proper 1/8th scale track buggy. Thus, you won’t see a Nomad on the track during the race, rules aside, in that it just wouldn’t be very much fun bringing up the rear every race.

I also do not consider the Nomad to be a true basher, like an ARRMA Kraton or Typhon. That’s not to say the Nomad couldn’t handle some pretty rough treatment, but it’s almost too composed and sedate for bashing. It doesn’t deliver the crazy level of speed common with bashers, nor does it feature demolition-derby styled front and rear bumpers. Some drivers comment that it jumps a bit nose heavy, making it unwieldy on ramp style jumps or at BMX parks.

It’s my opinion that the Nomad exists in a sweet spot right between a 1/8th scale racing buggy and a U4 Rock Racer, representing a very fine blend of those two racing elements. To speak to the Nomad’s versatility, little more is needed than a few different tire and pinion gear options to handle nearly any terrain you would want to drive in. The Nomad shines on common terrain; soccer fields, dirt lots, community parks, open desert spaces, and construction sites.

Unless you’re willing to spend nearly $250 for custom aluminum beadlock wheels with 17mm hubs from a company like Motoworx, you’re stuck running plastic wheels and glued tires. This is unfortunately because there are some excellent U4 racing tires out there on the market.

That said, out in open desert spaces, the Nomad easily devours dedicated rock racers with superior handling and a solid top-end speed of approximately 40 mph with the 15 tooth pinion gear. In anything but the chunkiest of technical terrain, the Nomad is going to have the advantage.

On the other side of the spectrum, the Nomad is too heavy and slow to keep up with any dedicated 1/8th scale track buggy. The suspension would need to be completely reworked and the body changed, and by then you might just as well get a proper 1/8th scale track buggy. Thus, you won’t see a Nomad on the track during the race, rules aside, in that it just wouldn’t be very much fun bringing up the rear every race.

I also do not consider the Nomad to be a true basher, like an ARRMA Kraton or Typhon. That’s not to say the Nomad couldn’t handle some pretty rough treatment, but it’s almost too composed and sedate for bashing. It doesn’t deliver the crazy level of speed common with bashers, nor does it feature demolition-derby styled front and rear bumpers. Some drivers comment that it jumps a bit nose heavy, making it unwieldy on ramp style jumps or at BMX parks.

It’s my opinion that the Nomad exists in a sweet spot right between a 1/8th scale racing buggy and a U4 Rock Racer, representing a very fine blend of those two racing elements. To speak to the Nomad’s versatility, little more is needed than a few different tire and pinion gear options to handle nearly any terrain you would want to drive in. The Nomad shines on common terrain; soccer fields, dirt lots, community parks, open desert spaces, and construction sites.

Nomad DB-8 making short work of this grassy hill.

Nomad DB-8 making short work of this grassy hill.

This allows the Nomad owner to find a suitable driving area near their home, and accessibility is an important part of the purchasing equation. In my city, there is only one true racing track about an hour drive from my house and no U4 Rock Racing to speak of, but literally hundreds of enjoyable areas within a 30 minute drive which are perfect for the Nomad.

Local parks tend to offer some of the most driving fun to be had with these vehicles and many communities have great parks to pick from. A small stack of plastic cones, and just about any open space can become a temporary race track. The less groomed the better. I’m partial to the worn-out soccer fields with their lumpy, dead grass which create glorious rooster tails of debris and dirt fanning out the back of the Nomad during full-speed runs.

Construction sites are worth checking out for a weekend morning session, just as long as you walk the area before you start speeding around. Aside from obvious dangers such as open trenches or exposed rebar, you need to keep an eye out for large rocks hidden in the fill dirt most construction lots are covered in. Plowing into a large hidden rock at full speed will bring just about any driving session to an abrupt end.

Considering this, the Nomad can fill the role of a “run anywhere” off road buggy in a person’s RC collection. Sometimes keeping things simple is the best way to have fun.

Local parks tend to offer some of the most driving fun to be had with these vehicles and many communities have great parks to pick from. A small stack of plastic cones, and just about any open space can become a temporary race track. The less groomed the better. I’m partial to the worn-out soccer fields with their lumpy, dead grass which create glorious rooster tails of debris and dirt fanning out the back of the Nomad during full-speed runs.

Construction sites are worth checking out for a weekend morning session, just as long as you walk the area before you start speeding around. Aside from obvious dangers such as open trenches or exposed rebar, you need to keep an eye out for large rocks hidden in the fill dirt most construction lots are covered in. Plowing into a large hidden rock at full speed will bring just about any driving session to an abrupt end.

Considering this, the Nomad can fill the role of a “run anywhere” off road buggy in a person’s RC collection. Sometimes keeping things simple is the best way to have fun.

First Run

A little body roll from the Nomad DB-8.

A little body roll from the Nomad DB-8.

After checking the 17mm wheel nuts and installing a charged 4s lipo battery, I headed out to the street for a quick test run and transmitter adjustment. Most RTR’s need a little adjustment to the steering for the vehicle to track straight.

Buzzing along the street and making a few low speed passes to adjust the steering on the transmitter, I gave it a bit more power to get a feel for the corning and acceleration.

Running around on the street out front, the Nomad was smooth and composed. The GT Grabber tires are soft and lean over a good amount when diving into the corners, lifting the inside wheel at the apex of the turn. Their rounded edge cleats and tight pattern give them a predictable feel on the asphalt.

This particular Nomad has a bit of positive camber in the rear wheels, so a little wrenching of the turnbuckles and the angle was adjusted to 2.0 degree negative camber. A few more laps around the street and the rear of the car felt more settled in the corners. The front was set almost neutral, so I added in 1.5 degrees of negative camber. I felt this would be a good starting point for testing.

The next thing to check was the shock fluid levels. Looking over the shocks, all four were properly filled to the top and was appeared to be a silicone oil in the 30 to 40 cst range. I wanted to specifically set up the shocks with TLR 45 cst oil in the front and 35 cst in the rear, and bleed them to have zero rebound. After draining the shocks and putting a bit of Noleen o-ring grease on the seals, I filled the shocks and worked the pistons to release any trapped air. The shocks use a bladder inside the shock cap, with two small weep holes on the side. This allows excess fluid to drain out when you tighten the cap after filling. I wouldn’t call this a venting hole because they are sitting on top of the thread form of the shock body and not further up behind the bladder.

A few more minutes to get the caps on and rebound set, and they were good to go.

I had kicked around the idea of pulling the three differentials and checking these over, but I opted to wait and inspect them after I got a number of testing sessions done. One of the aspects to a RTR is that indeed it’s actually ready to run. People shouldn’t need to pull differentials before their first outing with a new vehicle, yet I know it’s a common practice. For the time being, the Nomad’s differentials will be run “as is” from the factory.

Checking the rest of the Nomad over, everything else looked good and tight, and we were ready to go. The next morning would start the first testing session on grass, so batteries were charged and the equipment packed.

Buzzing along the street and making a few low speed passes to adjust the steering on the transmitter, I gave it a bit more power to get a feel for the corning and acceleration.

Running around on the street out front, the Nomad was smooth and composed. The GT Grabber tires are soft and lean over a good amount when diving into the corners, lifting the inside wheel at the apex of the turn. Their rounded edge cleats and tight pattern give them a predictable feel on the asphalt.

This particular Nomad has a bit of positive camber in the rear wheels, so a little wrenching of the turnbuckles and the angle was adjusted to 2.0 degree negative camber. A few more laps around the street and the rear of the car felt more settled in the corners. The front was set almost neutral, so I added in 1.5 degrees of negative camber. I felt this would be a good starting point for testing.

The next thing to check was the shock fluid levels. Looking over the shocks, all four were properly filled to the top and was appeared to be a silicone oil in the 30 to 40 cst range. I wanted to specifically set up the shocks with TLR 45 cst oil in the front and 35 cst in the rear, and bleed them to have zero rebound. After draining the shocks and putting a bit of Noleen o-ring grease on the seals, I filled the shocks and worked the pistons to release any trapped air. The shocks use a bladder inside the shock cap, with two small weep holes on the side. This allows excess fluid to drain out when you tighten the cap after filling. I wouldn’t call this a venting hole because they are sitting on top of the thread form of the shock body and not further up behind the bladder.

A few more minutes to get the caps on and rebound set, and they were good to go.

I had kicked around the idea of pulling the three differentials and checking these over, but I opted to wait and inspect them after I got a number of testing sessions done. One of the aspects to a RTR is that indeed it’s actually ready to run. People shouldn’t need to pull differentials before their first outing with a new vehicle, yet I know it’s a common practice. For the time being, the Nomad’s differentials will be run “as is” from the factory.

Checking the rest of the Nomad over, everything else looked good and tight, and we were ready to go. The next morning would start the first testing session on grass, so batteries were charged and the equipment packed.

A Note on Photos

Custom rock guards installed on the rear A-arms.

Custom rock guards installed on the rear A-arms.

Before we get into the testing results, I wanted to make a quick note about some of the details you will see in the photos. Unlike most reviews were the vehicle is run once or twice and then a “verdict” is made, I’ve spent over 200 hours behind the controls of the Nomad, evaluating every aspect of the buggy.

Like any driver, I made small adjustments here and there to help the review along, such as rock guards, while others changes were done to get extra value out of testing runs by evaluating an aftermarket part to substitute an OEM part. The following text is a short explanation of these changes.

The first item of note are the rock guards I made and added to the Nomad. After a few sessions in the medium rock and gravel, there was some wear starting to show on the rear suspension arms. The shock springs were also gradually losing their paint, and small pieces of rock were getting lodged in between the hinge pins and rear differential outdrives. Rather than tracking down a set of RC8.2 mud guards, I cut a set out of 1.5mm plastic sheeting and attached them to the rear lower suspension arms. These greatly reduced the amount of wear on the lower a-arms and also reduced the number of rocks working their way into the rear suspension. You will see these rock guards in some of the photos in this review.

Like any driver, I made small adjustments here and there to help the review along, such as rock guards, while others changes were done to get extra value out of testing runs by evaluating an aftermarket part to substitute an OEM part. The following text is a short explanation of these changes.

The first item of note are the rock guards I made and added to the Nomad. After a few sessions in the medium rock and gravel, there was some wear starting to show on the rear suspension arms. The shock springs were also gradually losing their paint, and small pieces of rock were getting lodged in between the hinge pins and rear differential outdrives. Rather than tracking down a set of RC8.2 mud guards, I cut a set out of 1.5mm plastic sheeting and attached them to the rear lower suspension arms. These greatly reduced the amount of wear on the lower a-arms and also reduced the number of rocks working their way into the rear suspension. You will see these rock guards in some of the photos in this review.

Aftermarket Hub (l) Compared to OEM Hub (r)

Aftermarket Hub (l) Compared to OEM Hub (r)

The next change are the use of aftermarket hubs on the Nomad during testing. While the Nomad evaluation was underway, I identified some spare parts which are hard to find, the extended hubs being one of them, but I was able to track down a few aftermarket options for the Nomad.

Knowing that I was going to be spending a lot of time testing the Nomad on different terrain, I decided to install these aftermarket hubs to see how they would hold up. These aftermarket hubs are dimensionally the same as the OEM hub, so it was mostly a matter of making sure the aluminum alloy would hold up to the abuse.

During the entire time of testing we experience no issues or problems with these hubs. I would change these back and forth from time to time with the OEM hubs, looking for a difference, but I could find none - other than the thread pitch.

For electronics, I changed out the receiver to a Spektrum unit, allowing me to use my DX5 – Pro transmitter. I have my other vehicles mapped to this transmitter, and I like the wider range of adjustments this unit offers.

Other than these items, I kept the Nomad as stock as possible to ensure we were evaluating exactly what the Team Associated RTR product had to offer.

Knowing that I was going to be spending a lot of time testing the Nomad on different terrain, I decided to install these aftermarket hubs to see how they would hold up. These aftermarket hubs are dimensionally the same as the OEM hub, so it was mostly a matter of making sure the aluminum alloy would hold up to the abuse.

During the entire time of testing we experience no issues or problems with these hubs. I would change these back and forth from time to time with the OEM hubs, looking for a difference, but I could find none - other than the thread pitch.

For electronics, I changed out the receiver to a Spektrum unit, allowing me to use my DX5 – Pro transmitter. I have my other vehicles mapped to this transmitter, and I like the wider range of adjustments this unit offers.

Other than these items, I kept the Nomad as stock as possible to ensure we were evaluating exactly what the Team Associated RTR product had to offer.

Testing Overview

Cleaned up after a long day of testing.

Cleaned up after a long day of testing.

Each session for the Nomad started the same with quick visual check chassis, electronics, body, and tires. I plugged in a battery and made a few slow passes to check transmitter function, and then right into testing.

Depending on the temperature outside, I would take breaks every 10 minutes of run time, measuring motor, ESC, and battery temperatures.

If cooling was needed, I would run a series of small fans across the electronics and recheck temperatures after a few minutes. After every battery pack there was a 10 minute cool down break under the fans.

Once a testing session was finished, the Nomad’s body was rinsed off and dried, and the chassis blown out with the compressor and wiped down with a wet rag to remove any remaining dirt or dust. Any rocks or debris remaining were removed with small tools.

Every few weeks the hinge pins and hub bearings were pulled and cleaned. Bearings were cleaned in an ultrasonic cleaner, blown dry, and then re-greased with Timken bearing grease.

After the cleaning process, I closely inspected the Nomad for any damaged parts or loose screws, making repairs or performing additional maintenance when necessary. During testing I did have a few items fail and those are discussed in detail later in this review.

Depending on the temperature outside, I would take breaks every 10 minutes of run time, measuring motor, ESC, and battery temperatures.

If cooling was needed, I would run a series of small fans across the electronics and recheck temperatures after a few minutes. After every battery pack there was a 10 minute cool down break under the fans.

Once a testing session was finished, the Nomad’s body was rinsed off and dried, and the chassis blown out with the compressor and wiped down with a wet rag to remove any remaining dirt or dust. Any rocks or debris remaining were removed with small tools.

Every few weeks the hinge pins and hub bearings were pulled and cleaned. Bearings were cleaned in an ultrasonic cleaner, blown dry, and then re-greased with Timken bearing grease.

After the cleaning process, I closely inspected the Nomad for any damaged parts or loose screws, making repairs or performing additional maintenance when necessary. During testing I did have a few items fail and those are discussed in detail later in this review.

Performance Testing

Nomad's GT Grabber tires provide excellent traction on grass.

Nomad's GT Grabber tires provide excellent traction on grass.

The primary goal was to test the Nomad out on a number of different surfaces and terrain which I felt were properly suited to the vehicle, with repeated visits to the testing locations to either verify previous results or update the notes.

Bashing or general mayhem was not part of the program, so while the Nomad was run hard, it was run in a reasonable fashion.

There were some instances of rubbing fenders with a few other RC cars while testing on the track, but nothing resembling a demolition derby.

I also avoided BMX style parks or similar jumps which would launch the Nomad into orbit. With that noted, let’s get into the results.

Bashing or general mayhem was not part of the program, so while the Nomad was run hard, it was run in a reasonable fashion.

There were some instances of rubbing fenders with a few other RC cars while testing on the track, but nothing resembling a demolition derby.

I also avoided BMX style parks or similar jumps which would launch the Nomad into orbit. With that noted, let’s get into the results.

Grass Testing

The faster the better with the Nomad DB-8.

The faster the better with the Nomad DB-8.

With grass being my favorite surface to drive on, I always start testing there for a number of reasons. First is that if the vehicle has a tendency to roll, grass is a bit more forgiving on the body panels and bumpers when the vehicle flips over.

I also feel that grass offers very good traction to test acceleration and braking without causing too much wear on the tires. By the time a few batteries are run through the buggy on grass, I have a pretty good feel for the handling characteristics and tipping points.

With a 4s lipo plugged in and the a quick check to make sure the grass field was clear, I took off on a long straight run to get the morning started. Blasting across one of our park’s well-used grass fields at full speed, the Nomad effortlessly cuts through the lumpy, uneven terrain. The 16mm shocks and suspension travel easily handles the grass surface, giving the Nomad somewhat of a serene look as it races along. There was no twitchiness to the handling, with smooth transitions into the corners and even power delivery from the drivetrain. For a factory suspension setup, the Nomad is very composed.

With the presence of thick, tall grassy areas in the field due to over-watering, I opted to use 8mm pre-load spacers on the shocks in the front and 10mm in the rear in order to raise the ride height. This kept the bottom of the chassis from dragging the top of the grass and overheating the motor.

The factory 15-tooth pinion gearing is setup for bottom-end torque and explosive acceleration, thus resulting in virtually no delay in getting up to full speed on the grass. Even when attacking the large sloping grassy hills surrounding the park, the Nomad maintained its speed.

I also feel that grass offers very good traction to test acceleration and braking without causing too much wear on the tires. By the time a few batteries are run through the buggy on grass, I have a pretty good feel for the handling characteristics and tipping points.

With a 4s lipo plugged in and the a quick check to make sure the grass field was clear, I took off on a long straight run to get the morning started. Blasting across one of our park’s well-used grass fields at full speed, the Nomad effortlessly cuts through the lumpy, uneven terrain. The 16mm shocks and suspension travel easily handles the grass surface, giving the Nomad somewhat of a serene look as it races along. There was no twitchiness to the handling, with smooth transitions into the corners and even power delivery from the drivetrain. For a factory suspension setup, the Nomad is very composed.

With the presence of thick, tall grassy areas in the field due to over-watering, I opted to use 8mm pre-load spacers on the shocks in the front and 10mm in the rear in order to raise the ride height. This kept the bottom of the chassis from dragging the top of the grass and overheating the motor.

The factory 15-tooth pinion gearing is setup for bottom-end torque and explosive acceleration, thus resulting in virtually no delay in getting up to full speed on the grass. Even when attacking the large sloping grassy hills surrounding the park, the Nomad maintained its speed.

Nomad DB-8 hooking a tight corner.

Nomad DB-8 hooking a tight corner.

The GT Grabber’s soft and flexible design provided solid traction on the grass, handling breaking and corners with excellent control.

Under hard acceleration out of the corners, I could feel some tire spin due to the conservative tread pattern and active differential, but the trade-off for smooth cornering was acceptable.

On a few dry spots in the field where the grass was beaten down and overworked, mashing the throttle as I entered these areas would break the tires free and induces some pretty cool rooster tails of dirt. A slight let-up on the throttle, and you’re back in control.

When moving over to some of the freshly mowed soccer fields, the Nomad felt firmly planted to the ground. While fast and nimble, there was a slightly muted sensation to its handling. The best way I can describe the feeling is that everything seems to have a half-second delay to radio input. The little bit of slip the grass gives is just enough to notice, but I was also a little suspicious of the servo being a bit slow.

Under hard acceleration out of the corners, I could feel some tire spin due to the conservative tread pattern and active differential, but the trade-off for smooth cornering was acceptable.

On a few dry spots in the field where the grass was beaten down and overworked, mashing the throttle as I entered these areas would break the tires free and induces some pretty cool rooster tails of dirt. A slight let-up on the throttle, and you’re back in control.

When moving over to some of the freshly mowed soccer fields, the Nomad felt firmly planted to the ground. While fast and nimble, there was a slightly muted sensation to its handling. The best way I can describe the feeling is that everything seems to have a half-second delay to radio input. The little bit of slip the grass gives is just enough to notice, but I was also a little suspicious of the servo being a bit slow.

Nomad's 2000 kV Reedy motor is putting down some power.

Nomad's 2000 kV Reedy motor is putting down some power.

The real fun on grass is found were the sections are over-used and neglected. The worse the grass conditions, the more enjoyable the Nomad was to drive.

Divots, lumps, dirt patches, and hidden depressions below the surface work the Nomad’s suspension and keep you on your toes.

If there is one thing the Nomad could use more of on this surface, it would be top-end speed. Running the 18 tooth or even 20 tooth pinion gears would be interesting in cooler weather.

Over the entire Nomad review period, I frequently returned to the grass fields in our area, making well over three dozen trips in total. Considering the results from all the different grass fields I ran the Nomad on, I feel this is an easy and fun terrain for anyone to drive.

Divots, lumps, dirt patches, and hidden depressions below the surface work the Nomad’s suspension and keep you on your toes.

If there is one thing the Nomad could use more of on this surface, it would be top-end speed. Running the 18 tooth or even 20 tooth pinion gears would be interesting in cooler weather.

Over the entire Nomad review period, I frequently returned to the grass fields in our area, making well over three dozen trips in total. Considering the results from all the different grass fields I ran the Nomad on, I feel this is an easy and fun terrain for anyone to drive.

Video Note: The following video was filmed with the Go Pro Hero 8 on Active Mode, Wide setting, Boost activated. The Go Pro is protected in a clear, waterproof hard case.

Asphalt Testing

More time on the asphalt.

More time on the asphalt.

Starting early one morning, I selected a large open parking lot and set up a small road course with a blend of sweeping corners, straights, and a few hairpin turns.

Initially I had thought to prepare the Nomad by lowering the ride height and use only a 2mm spacer in efforts to help drop the center of gravity, but I decided to save that for later on and just run with the same setting from the grass.

I did make sure the tires were fresh before we hit the track, so they were scrubbed clean of dirt from the last testing session. After a few passes around the track to warm up the tires, it was time to increase the speed.

With the torque from the 2000 kV Reedy motor, it was easy to break the tires free when getting on the throttle.

The GT Grabber tires are soft enough for solid traction, but the tire height off the wheel and soft inner foam allows the tire to fold over when entering the corners at speed. This usually results in a spin out if the corner is wide enough, but on the sharp hairpin turns, it will flip the Nomad over.

Initially I had thought to prepare the Nomad by lowering the ride height and use only a 2mm spacer in efforts to help drop the center of gravity, but I decided to save that for later on and just run with the same setting from the grass.

I did make sure the tires were fresh before we hit the track, so they were scrubbed clean of dirt from the last testing session. After a few passes around the track to warm up the tires, it was time to increase the speed.

With the torque from the 2000 kV Reedy motor, it was easy to break the tires free when getting on the throttle.

The GT Grabber tires are soft enough for solid traction, but the tire height off the wheel and soft inner foam allows the tire to fold over when entering the corners at speed. This usually results in a spin out if the corner is wide enough, but on the sharp hairpin turns, it will flip the Nomad over.

Nomad DB-8's planted straight-line acceleration.

Nomad DB-8's planted straight-line acceleration.

The soft suspension also resulted in a substantial amount of body roll, and between that and the tall, soft tires, you could really feel the weight shift to the outside of the corner with any speed.

The straight-line acceleration was very good with minimal tire spin, and the braking was also solid. Unless you were trying to lock up the tires, the Nomad would quickly come to a stop with a flick on the reverse.

On asphalt, you need to keep a relatively straight line when slowing down abruptly, or the suspension will compress and immediately flip the Nomad over.

Same thing with hard acceleration; any sudden direction change and the tires with the soft suspension will almost immediately flip you over. While the Nomad can run on asphalt, it’s not the ideal surface for the desert buggy.

On smooth, fresh asphalt, the Nomad can be fairly nimble. It’s not going to stick corners like a road car, which shouldn't come as any surprise, but with a little practice you can dive into power slides and have some pretty cool burnouts leaving the corners. Yes this does take some life out of the tires, but the Reedy motor will absolutely spin the tires on demand.

The straight-line acceleration was very good with minimal tire spin, and the braking was also solid. Unless you were trying to lock up the tires, the Nomad would quickly come to a stop with a flick on the reverse.

On asphalt, you need to keep a relatively straight line when slowing down abruptly, or the suspension will compress and immediately flip the Nomad over.

Same thing with hard acceleration; any sudden direction change and the tires with the soft suspension will almost immediately flip you over. While the Nomad can run on asphalt, it’s not the ideal surface for the desert buggy.

On smooth, fresh asphalt, the Nomad can be fairly nimble. It’s not going to stick corners like a road car, which shouldn't come as any surprise, but with a little practice you can dive into power slides and have some pretty cool burnouts leaving the corners. Yes this does take some life out of the tires, but the Reedy motor will absolutely spin the tires on demand.

It's impressive that the tires stayed on the wheels after this abuse.

It's impressive that the tires stayed on the wheels after this abuse.

If for some reason you wanted to spend more time on asphalt and run street tires, you can add on the RC8.2 sway bars and this will help plant the outside tire and minimize body roll.

Looking the tires over after a number of laps, they were showing some wear on the edges.

If you plan on running the Nomad on asphalt, I suggest switching out to a different set of tires. The GT Grabbers are just too soft for this surface.

As far as testing surfaces go, asphalt is my least favorite for this platform. I did return to the asphalt to test out a lower ride height setting; 3mm spacer in the front and a 5mm spacer in the rear, and there was some gain to the control in the corners. I was able to push faster into a few of the corners, but often times the rear end would break free and I would need to steer into the slide a bit to prevent spinning out.

When exiting the corners, the Nomad would remain in control even with maximum throttle input, showing just how well the GT tires handled the surface. I could hear them groan in the corners, and I was sure the rubber was quickly being abraded from the tires.

I only spent a few testing sessions out here on the asphalt; the GT Grabbers are good quality tires and not worth ruining. As a side note, I do have a set of Duratrax Badgers, and we did a little testing with those in the middle of this testing program, and they are quite fun on the blacktop.

Looking the tires over after a number of laps, they were showing some wear on the edges.

If you plan on running the Nomad on asphalt, I suggest switching out to a different set of tires. The GT Grabbers are just too soft for this surface.

As far as testing surfaces go, asphalt is my least favorite for this platform. I did return to the asphalt to test out a lower ride height setting; 3mm spacer in the front and a 5mm spacer in the rear, and there was some gain to the control in the corners. I was able to push faster into a few of the corners, but often times the rear end would break free and I would need to steer into the slide a bit to prevent spinning out.

When exiting the corners, the Nomad would remain in control even with maximum throttle input, showing just how well the GT tires handled the surface. I could hear them groan in the corners, and I was sure the rubber was quickly being abraded from the tires.

I only spent a few testing sessions out here on the asphalt; the GT Grabbers are good quality tires and not worth ruining. As a side note, I do have a set of Duratrax Badgers, and we did a little testing with those in the middle of this testing program, and they are quite fun on the blacktop.

Sand Testing

Nomad DB-8 ready for a day in the sand.

Nomad DB-8 ready for a day in the sand.

In some ways driving a buggy in sand is a bit like you owning a boat versus your best friend owning a boat; it’s better to leave the maintenance to someone else. That said, it makes little sense to evaluate a desert buggy without a brief run in the sand, so I made some room in the maintenance schedule for a complete cleaning and headed out.

Leaving the cones at home and taking a fine leaf rake, I headed over to the volley ball court early one morning and raked the sand smooth. Might as well get the sand in a perfect condition before making a few runs.

As I plugged in the battery, I wondered just how much sand would end up packing into the differentials and electronics.

After snapping a few glamor shots before getting dirty, I made a few low-speed passes in the soft sand. The sand filling the volleyball court is extremely dry from sitting out in the baking sun for the past few months with no rain. Mixed in with the sand was a bit of gravel and fine a powder, for a depth around five inches.

The gravel give the sand just enough body for the tires to bite into, but launching from a dead stop under full power can take a moment before you get moving.

Leaving the cones at home and taking a fine leaf rake, I headed over to the volley ball court early one morning and raked the sand smooth. Might as well get the sand in a perfect condition before making a few runs.

As I plugged in the battery, I wondered just how much sand would end up packing into the differentials and electronics.

After snapping a few glamor shots before getting dirty, I made a few low-speed passes in the soft sand. The sand filling the volleyball court is extremely dry from sitting out in the baking sun for the past few months with no rain. Mixed in with the sand was a bit of gravel and fine a powder, for a depth around five inches.

The gravel give the sand just enough body for the tires to bite into, but launching from a dead stop under full power can take a moment before you get moving.

Nomad's GT Grabbers provide solid traction in the loose sand.

Nomad's GT Grabbers provide solid traction in the loose sand.

Under power, the soft Nomad tires had impressive traction for such a tight tread pattern and narrow footprint. The differential setup didn’t have too much slipping to the unloaded tire.

Attacking the corners at speed, I could feel the power transfer from the differentials as the tires clawed their way through the deep sand.

In a straight line, there was minimal drifting at full power, but unfortunately the volleyball court wasn’t long enough to reach top speed. Thus most of the power runs were shorter than I wanted, but long enough to see that the wide stance and smooth power delivery from the motor resulted in surprisingly nimble performance in the sand.

I think with wider, more aggressive tires and a bump up in the differential fluid, the Nomad could really fly on sand.

Knowing that sand is almost as bad as saltwater for RC vehicles, I worked quickly with the camera while my youngest son, Alex, was behind the wheel. At ten years old, he is a good driver, but will tend to head into corners a bit too hot.

On the sand, if he stayed on the throttle as he made a tight corner, the Nomad would dig in the front outside tire and flip in an instant. The sand offers very little warning before you’re looking and the bottom the chassis as the Nomad flips over onto its roof. When he would enter a corner and come off the throttle completely, the rear end of the Nomad would whip around smoothly. After a few more test runs of this technique, Alex could spin the Nomad to a stop right in front of the video camera.

Attacking the corners at speed, I could feel the power transfer from the differentials as the tires clawed their way through the deep sand.

In a straight line, there was minimal drifting at full power, but unfortunately the volleyball court wasn’t long enough to reach top speed. Thus most of the power runs were shorter than I wanted, but long enough to see that the wide stance and smooth power delivery from the motor resulted in surprisingly nimble performance in the sand.

I think with wider, more aggressive tires and a bump up in the differential fluid, the Nomad could really fly on sand.

Knowing that sand is almost as bad as saltwater for RC vehicles, I worked quickly with the camera while my youngest son, Alex, was behind the wheel. At ten years old, he is a good driver, but will tend to head into corners a bit too hot.

On the sand, if he stayed on the throttle as he made a tight corner, the Nomad would dig in the front outside tire and flip in an instant. The sand offers very little warning before you’re looking and the bottom the chassis as the Nomad flips over onto its roof. When he would enter a corner and come off the throttle completely, the rear end of the Nomad would whip around smoothly. After a few more test runs of this technique, Alex could spin the Nomad to a stop right in front of the video camera.

Pushing through the corners during some testing.

Pushing through the corners during some testing.

Once I had the photos and videos finished up, we raced around the perimeter of the sand court, hitting the small mounds of sand some of the kids had built up the day before. Not surprisingly, the Nomad sailed off the small mounds and stuck landings without missing a beat.

Testing in the sand was enjoyable, and I think some time in the future a trip to the beach is in order for some more driving fun.

Unlike the other surfaces where multiple testing sessions were scheduled, I only did one day in the sand. Heading back home I was able to blow off just about all of the sand from the corners of the Nomad, but I still ended up pulling the entire buggy apart and servicing all three differentials as well as the bearings from the entire drivetrain.

During the servicing of the shocks, I found a good amount of sand built up on the inside of the boots; actually there was sand just about everywhere on the Nomad. A few hours later and we were ready for the next testing session. While the sand is fun to drive on, the following maintenance is considerable. Just something to keep in mind when hitting the sand dunes over the weekend.

Testing in the sand was enjoyable, and I think some time in the future a trip to the beach is in order for some more driving fun.

Unlike the other surfaces where multiple testing sessions were scheduled, I only did one day in the sand. Heading back home I was able to blow off just about all of the sand from the corners of the Nomad, but I still ended up pulling the entire buggy apart and servicing all three differentials as well as the bearings from the entire drivetrain.

During the servicing of the shocks, I found a good amount of sand built up on the inside of the boots; actually there was sand just about everywhere on the Nomad. A few hours later and we were ready for the next testing session. While the sand is fun to drive on, the following maintenance is considerable. Just something to keep in mind when hitting the sand dunes over the weekend.

Gravel and Small Rock Testing

Nomad DB-8 buzzing along the gravel.

Nomad DB-8 buzzing along the gravel.

Following the same approach with the testing on asphalt, I set up a small course on a large dirt and gravel construction lot, consisting of similar sweeping corners, straights, and hair-pin turns. The surface is loose gravel and small rock covering a hard, sun-baked dirt base. Coming as no surprise, the Nomad simply flies over this surface.

Staying with the shocks running 45/35 weight TLR silicone oil and the OEM springs, I went with a 10mm spacer in the back and 8mm in the front. There are enough larger rocks blended in to the track that anything lower and the Nomad is going to start catching the chassis bottom frequently.

Hooking the corners resulted in gravel-spewing slides and on-power drifts, with plenty of control to pick which line you want on the exit. That said, coming in too hot isn’t going to be solved by any suspension or tire setup; you still have to watch your speed or you’re going to end up in the bushes.

On the straight sections, I could run full power and the Nomad would track the line precisely. When the surface became fine and dusty, the rear end would start to drift out a bit and the tires felt on the edge of breaking free. There is more than enough power to break the tires free at anything short of top speed, and a few session were I was racing other vehicles and I would give it too much throttle trying to pull away. At times I would lose control and the Nomad would slide out, requiring me to either lift or gently feather the brakes to regain control.

Staying with the shocks running 45/35 weight TLR silicone oil and the OEM springs, I went with a 10mm spacer in the back and 8mm in the front. There are enough larger rocks blended in to the track that anything lower and the Nomad is going to start catching the chassis bottom frequently.

Hooking the corners resulted in gravel-spewing slides and on-power drifts, with plenty of control to pick which line you want on the exit. That said, coming in too hot isn’t going to be solved by any suspension or tire setup; you still have to watch your speed or you’re going to end up in the bushes.

On the straight sections, I could run full power and the Nomad would track the line precisely. When the surface became fine and dusty, the rear end would start to drift out a bit and the tires felt on the edge of breaking free. There is more than enough power to break the tires free at anything short of top speed, and a few session were I was racing other vehicles and I would give it too much throttle trying to pull away. At times I would lose control and the Nomad would slide out, requiring me to either lift or gently feather the brakes to regain control.

Nomad DB-8 taking off for another gravel sprint.

Nomad DB-8 taking off for another gravel sprint.

Like any loose surface, clamping down on the throttle with a 2000 kv motor in a 1/8th buggy is going to break the tires loose.

Developing a feel for just how hard you can push the Nomad and remain in control takes a few minutes to figure out, and can change depending on the specific surface you’re running on.

Often you will read discussion about differential oil setup and how it influences a buggy’s performance, and gravel is one surface where you will really see the difference.

According to the manual, the factory oil setup is 20 / 20 / 20k cst, and with this the Nomad feels in control racing around the track but retains a playful feel to the handling.

The Nomad’s buggy body keeps most of the small rocks from kicking up into the chassis, but after an afternoon on gravel or rock, there are always a few pieces tucked around the drive shafts and electrical components. Because of the spacing between the components, these tend to not result in any damage, but there are the random few which get wedged between the bottom half of the outdrives of the rear differential and lower a-arm pivot pin. Mud guards would keep these away, and I ended up making a set after a few more of these testing sessions.

I was able to run this course multiple times over the period of three days straight, with each session using up four 4s lipo batteries. This usually provided almost three hours of track time per session with a few cooling periods in between.

Bringing each gravel track session to a close, I fired up the air compressor and cleaned off all the dust and rock from the Nomad’s body and chassis. Aside from picking the random bits of gravel out from a few spots in the battery tray, I could not find anything amiss from the hard driving.

Developing a feel for just how hard you can push the Nomad and remain in control takes a few minutes to figure out, and can change depending on the specific surface you’re running on.

Often you will read discussion about differential oil setup and how it influences a buggy’s performance, and gravel is one surface where you will really see the difference.

According to the manual, the factory oil setup is 20 / 20 / 20k cst, and with this the Nomad feels in control racing around the track but retains a playful feel to the handling.

The Nomad’s buggy body keeps most of the small rocks from kicking up into the chassis, but after an afternoon on gravel or rock, there are always a few pieces tucked around the drive shafts and electrical components. Because of the spacing between the components, these tend to not result in any damage, but there are the random few which get wedged between the bottom half of the outdrives of the rear differential and lower a-arm pivot pin. Mud guards would keep these away, and I ended up making a set after a few more of these testing sessions.

I was able to run this course multiple times over the period of three days straight, with each session using up four 4s lipo batteries. This usually provided almost three hours of track time per session with a few cooling periods in between.

Bringing each gravel track session to a close, I fired up the air compressor and cleaned off all the dust and rock from the Nomad’s body and chassis. Aside from picking the random bits of gravel out from a few spots in the battery tray, I could not find anything amiss from the hard driving.

Brake check in 3...2...1....

Brake check in 3...2...1....

After the first two sessions on gravel, I decided to pull differentials for a closer look. I wanted to see how much dust and dirt had worked into the front and rear bulkheads. It was also a chance for me to service the differential and look for any wear or fluid issues.

Surprisingly these were relatively clean with just a little brown dust mixed in with the grease around the differential itself, and inside the differential the fluid was a medium grey color.

The differential gears were all in good shape, so I cleaned everything out and refilled them with the same 20 / 20 / 20k cst TLR diff fluid, but I think after testing I will experiment more with differential fluid viscosities and reevaluate the performance.

Back out on the track, the Nomad felt a touch more squirrelly while in the tight corners, but was able to put impressive power down exiting the turns. My guess is that the factory diff fluid is probably different than the TLR fluid I use, and I could see a reduced amount of unloading to the front tires when Nomad was in the choppy edges of the track.

Surprisingly these were relatively clean with just a little brown dust mixed in with the grease around the differential itself, and inside the differential the fluid was a medium grey color.

The differential gears were all in good shape, so I cleaned everything out and refilled them with the same 20 / 20 / 20k cst TLR diff fluid, but I think after testing I will experiment more with differential fluid viscosities and reevaluate the performance.

Back out on the track, the Nomad felt a touch more squirrelly while in the tight corners, but was able to put impressive power down exiting the turns. My guess is that the factory diff fluid is probably different than the TLR fluid I use, and I could see a reduced amount of unloading to the front tires when Nomad was in the choppy edges of the track.

Ready for another speed run.

Ready for another speed run.

Unlike the asphalt which causes rapid wear on the tires, I was surprised to see only a minor amount of abrasive wear on the sides of the tire. The glue was still holding up very well and there were no areas of separation of the tire from the wheel.

With the current setup on the Nomad, I continued to run various track courses on the gravel surface with excellent results. Each day the track was set up differently, either to increase the distance of the straight sections, or to include more choppy terrain in the corners. With these changes, the Nomad continued to drive exceedingly well.

I felt on the longer sections, much like the grass, the Nomad could handle a taller pinion gear for more speed. The suspension setup smooths out the rocks and chatter very well, and there is an unusual confidence at speed that the Nomad brings. Unlike some bashers, it’s not searching for a straight line to hold, but rather it holds a line until you make a change.

I do think a rear sway bar would be useful on this surface and something worth considering if can track one down. Along with the sway bar, a set of the Factory Team shock springs and some experimentation with the shock fluid and piston sizes.

With the current setup on the Nomad, I continued to run various track courses on the gravel surface with excellent results. Each day the track was set up differently, either to increase the distance of the straight sections, or to include more choppy terrain in the corners. With these changes, the Nomad continued to drive exceedingly well.

I felt on the longer sections, much like the grass, the Nomad could handle a taller pinion gear for more speed. The suspension setup smooths out the rocks and chatter very well, and there is an unusual confidence at speed that the Nomad brings. Unlike some bashers, it’s not searching for a straight line to hold, but rather it holds a line until you make a change.

I do think a rear sway bar would be useful on this surface and something worth considering if can track one down. Along with the sway bar, a set of the Factory Team shock springs and some experimentation with the shock fluid and piston sizes.

Back on the Duratrax Badgers.

Back on the Duratrax Badgers.

The gravel presents such a fun surface to drive that I continued to revisit this area on weekends for additional track time with the Nomad, even switching back to the Duratrax Badger tires for a few races against a few of the local drivers.

The switch of tires was mostly due to the idea of testing the factory GT tires under “nominal testing conditions” and not racing my friends.

Well, when you’re going up against a few racers, one of them running a Traxxas UDR on 6s, all bets are off and I’m going in for the win, and it’s gonna be ugly for the tires.

With this type of driving, there is always a risk of slashing a tire when you need to push someone out of the way, so the Duratrax Badgers were the choice.

The switch of tires was mostly due to the idea of testing the factory GT tires under “nominal testing conditions” and not racing my friends.

Well, when you’re going up against a few racers, one of them running a Traxxas UDR on 6s, all bets are off and I’m going in for the win, and it’s gonna be ugly for the tires.

With this type of driving, there is always a risk of slashing a tire when you need to push someone out of the way, so the Duratrax Badgers were the choice.

Running down that checkered flag for another win..!

Running down that checkered flag for another win..!

After running a number of heats, I found the Nomad to be very well suited for this style of driving.

If there is one “perfect” terrain for the Nomad, it has to be gravel and small rock.

It simply oozes the racing pedigree from Team Associated, but with a level of robustness to handle going fender to fender on the track.

It feels more like a burly 1/8 track car than a rock racer, and I’m very much looking forward to running against the new Losi Lasernut U4 in the near future.

If there is one “perfect” terrain for the Nomad, it has to be gravel and small rock.

It simply oozes the racing pedigree from Team Associated, but with a level of robustness to handle going fender to fender on the track.

It feels more like a burly 1/8 track car than a rock racer, and I’m very much looking forward to running against the new Losi Lasernut U4 in the near future.

The Grabber tire from General Tire held up very well to the abuse, but they finally wore down.

The Grabber tire from General Tire held up very well to the abuse, but they finally wore down.

Weeks later we were back on the track and I was struggling to find traction in some of the looser sections of rock and dirt with the GT tires.

The power slides were quite fun, but I was leaving some acceleration performance on the table due to the GT tires looking for traction.

In between batteries, I was checking the tires over, and I found that not only had I worn holes in-between the cleats on the inside of the tires, but the rear tires felt almost flat. I was suspicions that the tire foams had finally started to fail.

I installed new factory wheels and tires to finish off the day, and there was some improvement in traction, I was still sliding quite a bit. Under normal driving conditions it’s not such an issue, but an upgrade to the tires might help get power better delivered to the ground. I was certain it would help immensely during our weekend races.

The power slides were quite fun, but I was leaving some acceleration performance on the table due to the GT tires looking for traction.

In between batteries, I was checking the tires over, and I found that not only had I worn holes in-between the cleats on the inside of the tires, but the rear tires felt almost flat. I was suspicions that the tire foams had finally started to fail.

I installed new factory wheels and tires to finish off the day, and there was some improvement in traction, I was still sliding quite a bit. Under normal driving conditions it’s not such an issue, but an upgrade to the tires might help get power better delivered to the ground. I was certain it would help immensely during our weekend races.

Motoworx aluminum beadlocks with 2.2 tires and single-stage foams.

Motoworx aluminum beadlocks with 2.2 tires and single-stage foams.

With that said, I ordered a set of Motoworx aluminum beadlock wheels.

With the a few different colored front rings and a set of 0.200” hub extensions, these were a cool $300 plus shipping.

I had a set of EBay Rock Beast 2.2 tires that were too hard from crawling, so I installed them on the new wheels once they arrived.

Mounting them on the Nomad, the stance grew noticeably wider and I was somewhat concerned about excessive tire scrubbing on the front end. The spacers were needed to clear the hubs, so I had little choice as to how these would fit on the desert buggy. Until a 2.2” / 3.0 beadlock is figured out with a 17mm hub, this is the only real option on the market.

Back out on the track, it was considerable improvement in traction. I made a number of passes around the track, and while I could feel the scrubbing in the front, the corners were so blown out and wide that I didn’t find it to be much of a concern. On a tighter track with high-traction, it could be an issue with the noticeable understeer that I could clearly feel.

To deal with this understeer, I entered the corners a bit slower and then pressed the speed as I approached the apex of the curve. The improved traction at the apex off-set the understeer, and ultimately I felt faster as I exited the corners with these wheels and tires as I did with the OEM GT Grabbers.

With the a few different colored front rings and a set of 0.200” hub extensions, these were a cool $300 plus shipping.

I had a set of EBay Rock Beast 2.2 tires that were too hard from crawling, so I installed them on the new wheels once they arrived.

Mounting them on the Nomad, the stance grew noticeably wider and I was somewhat concerned about excessive tire scrubbing on the front end. The spacers were needed to clear the hubs, so I had little choice as to how these would fit on the desert buggy. Until a 2.2” / 3.0 beadlock is figured out with a 17mm hub, this is the only real option on the market.

Back out on the track, it was considerable improvement in traction. I made a number of passes around the track, and while I could feel the scrubbing in the front, the corners were so blown out and wide that I didn’t find it to be much of a concern. On a tighter track with high-traction, it could be an issue with the noticeable understeer that I could clearly feel.

To deal with this understeer, I entered the corners a bit slower and then pressed the speed as I approached the apex of the curve. The improved traction at the apex off-set the understeer, and ultimately I felt faster as I exited the corners with these wheels and tires as I did with the OEM GT Grabbers.

Dropping the pack like a bad habit; these Motoworx wheels are superb.

Dropping the pack like a bad habit; these Motoworx wheels are superb.

After running a battery through the Nomad, I had a feel for my lines and speed, so I went back into the pits for a cool down and fresh battery.

The UDR was powered up as the chase vehicle and the Go Pro was fired up.

Rolling out from the pits, I immediately took off and kept it going hard for the next few minutes.

The Nomad was far better at getting power to the track and exiting the corners fast. A light tap on the brakes when I over shot a turn would bring the Nomad back on line quickly without sliding out into the rough.

Running the straight sections between the corners, the Nomad would surge ahead of the UDR chase vehicle with superior traction, and only a slight torque drifting with the car ever so slightly shifting to the left as the rear of the Nomad drifted to the right.

I noticed it a few times where I exited a corner perfectly and had a long, straight shot to the far corner of our track. This straight shot is exiting corner number four and cutting thirty yards diagonally across the track, and the Nomad is under full power for that entire sprint. It is the one area where the UDR can gain ground quickly due to its inherently greater speed, but only if it can find traction.

The UDR was powered up as the chase vehicle and the Go Pro was fired up.

Rolling out from the pits, I immediately took off and kept it going hard for the next few minutes.

The Nomad was far better at getting power to the track and exiting the corners fast. A light tap on the brakes when I over shot a turn would bring the Nomad back on line quickly without sliding out into the rough.