Traxxas TRX-4 2021 Bronco

|

Why the TRX-4

It was late 2022, and during a discussion about testing plans for the 2023 crawling season, it became apparent that within our fleet of a dozen or so crawlers, we didn’t have a standard trail truck. All of our full-bodied trucks had been tuned and adjusted for maximum crawling performance with most of the scale details removed, OEM parts replaced with lighter options, and electronics stripped down to the bare minimum. I felt this created a bit of a gap between the results found with our trucks versus what many of our readers would see with their own trail / crawler trucks. We needed to add another truck to the testing fleet which is closer in configuration to what was more prevalent out on the trail. |

|

Our idea is that a "standard trail truck" would be something widely popular in the RC community and can be found in most RC hobby stores. These also tend to be RTR units rather than kits or custom builds.

Some of the more popular RTR trail trucks on the market come equipped with a two-speed transmission, allowing you to shift into high-gear and quickly drive along smoother sections the trail, and then downshift into a lower gear range for slow and controlled rock crawling. This feature interested us greatly, and currently none of the crawlers in our fleet have a two-speed transmission. We also wanted something that was a bit more visually appealing with attention paid to the scale details and a high-quality hard plastic body. For many RC drivers who are not dedicated crawlers, a good looking standard trail truck of this nature might be their first and possibly only vehicle filling such a slot in their collection. |

It didn't take much discussion to figure out which RC platform best checks all the boxes; the Traxxas TRX-4. The TRX-4 lineup from Traxxas starts at the budget-oriented kit level and rolls all the way up to their flagship RTR model, the TRX-4 2021 Bronco. This trail truck has the looks and the nifty features which set it apart from the rest of our fleet, and we’re total suckers for the Bronco.

There was one other truck we considered, and it was the Vanquish Phoenix RTR trail truck. This unit is new on the market, and an interesting market move for Vanquish. Arguably the Phoenix kit is dollar for dollar the best kit on the market today, but the transmission features of the kit and RTR did quite line up with our goals for this project. Thus, that truck was ruled out.

There was one other truck we considered, and it was the Vanquish Phoenix RTR trail truck. This unit is new on the market, and an interesting market move for Vanquish. Arguably the Phoenix kit is dollar for dollar the best kit on the market today, but the transmission features of the kit and RTR did quite line up with our goals for this project. Thus, that truck was ruled out.

|

TRX-4 2021 Bronco

The Traxxas TRX-4 2021 Bronco might just be the best-looking scale trail truck / rock crawler on the market today, but retailing at $500, it's also one of the more expensive options. On this model, Traxxas took the approach of combining their best technical features for modern rock crawlers and trails trucks into one well-rounded and surprisingly detailed trail and rock crawling package. While we don’t often reference YouTube channels or outside content, the detailed video produced by Scale Builder’s Guild on this truck is well laid out and covers in considerable detail all the unique features of this version of the TRX-4. I’ve linked the video HERE for those who would like to check that out. |

|

The TRX-4 2021 Bronco ( we will just refer to it from here on out as the TRX-4 ) has three important features which significantly expand its performance out on the trail. These features are:

First two features are pretty straight forward in that portal axles provide additional ground clearance and the two-speed transmission provides you with a high gear for faster trail driving and a low gear for rock crawling. Traxxas is not the only company to have these two features, but I feel they do the best job in executing this technology for the 1/10 scale class. |

A third and more uncommon feature of the TRX-4 is the ability to lock and unlock the front and rear differentials individually. The advantage of this is when driving along the trail in high gear, you run the differentials unlocked. Unlocked differentials allow the two wheels on the axle to spin at different speeds. This in turn gives you a much smoother driving feel and tighter turning radius.

When you encounter rough terrain or a pile of rocks you wish to summit, you first downshift into low gear and then lock the front and rear differentials. As a side note, on the TRX-4 you can actually lock just the front differential, leaving the rear differential open. I personally don't do this, but rather I lock both at the same time so the rear tires have maximum traction on the really steep climbs. Once the differentials are locked, you're truly in four-wheel drive and ready to crawl you way to the top.

Once you're through the rough terrain, you can unlock the differentials and shift back into high gear for smooth trail cruising. This is the exact same process you would follow in a 1:1 off-road truck, highlighting Traxxas' attention to detail in the scale aspect of this truck.

If you want a closer look as to how a differential mechanism works, here is a short clip showing the basic mechanics: LINK.

When you encounter rough terrain or a pile of rocks you wish to summit, you first downshift into low gear and then lock the front and rear differentials. As a side note, on the TRX-4 you can actually lock just the front differential, leaving the rear differential open. I personally don't do this, but rather I lock both at the same time so the rear tires have maximum traction on the really steep climbs. Once the differentials are locked, you're truly in four-wheel drive and ready to crawl you way to the top.

Once you're through the rough terrain, you can unlock the differentials and shift back into high gear for smooth trail cruising. This is the exact same process you would follow in a 1:1 off-road truck, highlighting Traxxas' attention to detail in the scale aspect of this truck.

If you want a closer look as to how a differential mechanism works, here is a short clip showing the basic mechanics: LINK.

|

Our TRX-4 arrived as a ready-to-run ( RTR ) truck right out of the box. A close inspection of the truck uncovered nothing amiss or out of place. The build quality was rather impressive for an RTR, and the transmitter calibrated and all shifting servos worked properly.

After some additional inspection steps, we packed up the truck and headed off to our U4 desert racetrack to see just how well the adjustable transmission and differential settings would enhance the truck’s performance. We also removed the spare tire from the back of the truck. I like the scale details to a point, but hauling the extra weight around on an RC crawler in the form of a spare tire is a bit too much. The final change, and it's only for running on this track, was installing a set of aluminum beadlock wheels with JConcepts Landmine tires. We didn't want to foul up the OEM tires just yet. |

Much to our surprise, the TRX-4 did shockingly well on the U4 desert track. Being able to down-shift and lock the differentials allows the truck to easily work its way through the chunky rock gardens by utilizing the full four-wheel drive aspect of locked differentials.

Upon exiting the rock garden, with the flick of two switches on the transmitter, the transmission switches back into high gear and the differentials unlock, and we were cruising along at high speed while negotiating the tight turns and straightaways of the desert track.

We fooled around with running the TRX-4 on the track a few more times, and while the idea of developing the TRX-4 into a 1.9” rock racing machine is highly appealing, we wanted to stay with our original plan to use this as tire testing platform.

Upon exiting the rock garden, with the flick of two switches on the transmitter, the transmission switches back into high gear and the differentials unlock, and we were cruising along at high speed while negotiating the tight turns and straightaways of the desert track.

We fooled around with running the TRX-4 on the track a few more times, and while the idea of developing the TRX-4 into a 1.9” rock racing machine is highly appealing, we wanted to stay with our original plan to use this as tire testing platform.

|

First Assessment Notes

Out on the trail, the TRX-4 is surprisingly composed and enjoyable to drive. The high-speed gearing allows you to walk behind the truck at a good pace as you drive along the trail or on towards the next pile of rocks. When running in the high-speed setting, we kept the front and rear differentials unlocked to maintain the smooth driving characteristics. Now there is an important thing about the front and rear differentials of the TRX-4 (there is no center differential, but rather a slipper-pad setup) worth mentioning; the differentials are not completely sealed. If you pull apart the differential from a 1/8 buggy or 1/10 SCT, you would find rubber O-rings sealing the outputs on each side of the differential. These O-rings prevent the silicone fluid inside the differential from leaking out. Silicone fluid dictates the level of resistance between the internal gears of the differential, and it's an important aspect to adjust and tune the handling characteristics of a racing buggy or SCT. Thicker fluid applies power more evenly between the two tires where as thinner fluid allows one tire to spin more freely when the other encounters resistance. |

|

With the TRX-4, axle rotation velocity is much, much lower, meaning that the silicone fluid is far less likely to spin out of the differential and significantly degrade the performance when running the differentials unlocked.

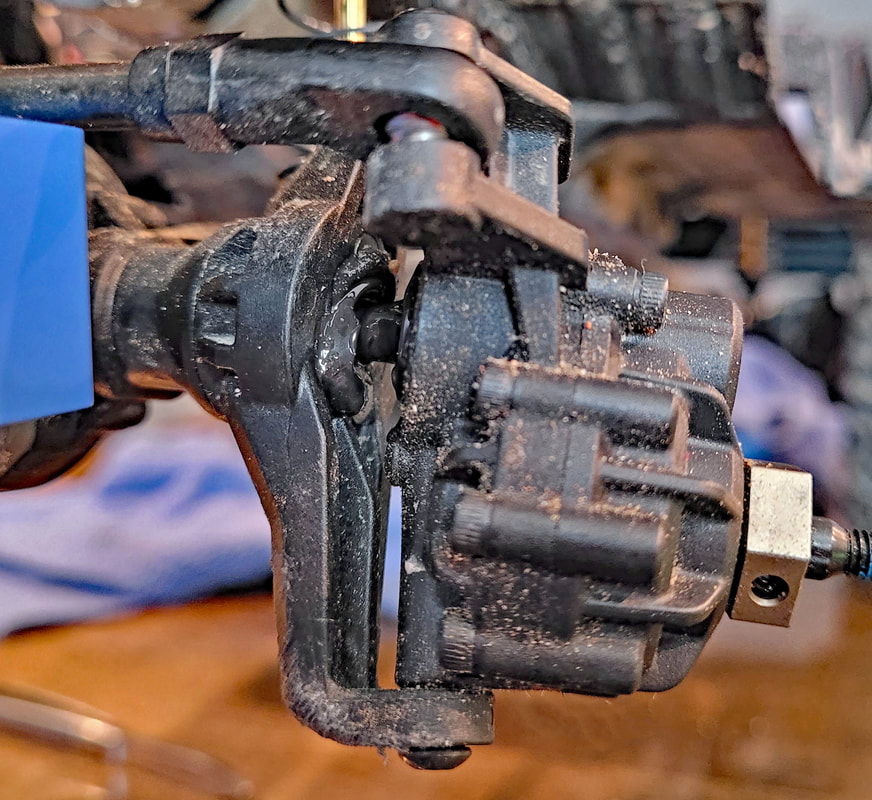

Even with a small leaking of fluid, you’ll most likely not notice any negative effects out on the trail. This is also a situation where grease may be a better choice than silicone fluid for the differentials in that it will tend to stay put for longer periods. The on-line owner’s manual is a bit vague about what to fill the differentials with, but they do mention grease for the transmission as well as the ring and pinion gears. All of that said, we did notice the fluid leaking out after running the TRX-4 on our U4 track. The sustained high-speed driving was enough to force the fluid out of the differential, down through the axle tube and out the inner side of the portal. It made quite the mess. We opted to refill our differentials with 10k wt oil, knowing that it will slowly leak out over time. I’m not terribly concerned about this and most likely switch over to a grease during the next service session. |

There are a number of key points here to keep in mind:

I feel I've made a mountain out of a mole hill, but it's something I noticed and wanted to share with you guys. Interesting, I haven't see it mentioned on any forums or reviews. Either we are way into the proverbial weeds on this topic, or maybe it's being overlooked. My guess is that we are in the weeds.

- This is an area of maintenance you should keep an eye on when servicing your TRX-4.

- Are the lack of O-ring seals a deal breaker for us? No.

- Will it affect 98% of the owners out there for trailing and crawling? No.

- Once you lock the differentials, this is a non-issue; the gears are locked and the tires must spin at the same rate.

- Could it be an issue for rock racing the TRX-4? Possibly.

I feel I've made a mountain out of a mole hill, but it's something I noticed and wanted to share with you guys. Interesting, I haven't see it mentioned on any forums or reviews. Either we are way into the proverbial weeds on this topic, or maybe it's being overlooked. My guess is that we are in the weeds.

|

Moving On

Unlike our VS 410 Pro and the Element Ecto, the TRX-4's portal axle setup and provides an additional half-inch of clearance over a straight axle of similar housing design, and in a crawling aspect this is highly advantageous. The only issue with running portal axles is the elevated center of gravity with the truck. I’m sure most of you have either read or heard some discussion about the advantages / disadvantages of portal axles in this regard, but that’s very much terrain dependent and personal preference. For our needs, terrain, and overall expectations, portal axles pose no measurable disadvantage on the majority of our trails. Looking over our fleet, we are running three crawlers with portals, now a fourth counting the TRX-4. The remainder are straight axles. |

Additional Thoughts

Initially, I didn’t think I would use the shifting functions of the TRX-4 very much. My thought was that I’d stick to crawling rocks in a similar fashion as with the other trucks in our fleet, but that turned out not to be the case. More often than I had anticipated, I found myself cruising along the trail in high gear, checking out smaller rocky outcroppings which I hadn’t deemed “worthy” or technically challenging enough to engage with the other trucks.

At first I would try these smaller rocky sections of trail in low gear, but with open differentials, looking to see if I could work my way up or around. If I came up short, I’d back off a bit, lock both differentials and try again. Usually I’d motor right on up and past what was giving me trouble. I found this interesting and enjoyable, and it further grew my appreciation for the TRX-4. Having the ability to downshift into a low gear and lock the differentials brings a surprisingly capable dimension of rock crawling prowess to a nimble and quick trail truck.

I also tended to drive the TRX-4 for longer durations when out on the trail, and this had me thinking over the battery capacity I was selecting. Our lightweight 450 and 850 batteries didn’t have the capacity I was looking for, so I started experimenting with the 1500 mAh batteries for a longer running time.

With a dozen trail sessions under our belt, it was time to head into the shop and start making some changes. Again, the goal was not to lose the TRX-4 identity through the upgrade / modification process, but to enhance what it's all about; trail cruising and rock crawling.

Initially, I didn’t think I would use the shifting functions of the TRX-4 very much. My thought was that I’d stick to crawling rocks in a similar fashion as with the other trucks in our fleet, but that turned out not to be the case. More often than I had anticipated, I found myself cruising along the trail in high gear, checking out smaller rocky outcroppings which I hadn’t deemed “worthy” or technically challenging enough to engage with the other trucks.

At first I would try these smaller rocky sections of trail in low gear, but with open differentials, looking to see if I could work my way up or around. If I came up short, I’d back off a bit, lock both differentials and try again. Usually I’d motor right on up and past what was giving me trouble. I found this interesting and enjoyable, and it further grew my appreciation for the TRX-4. Having the ability to downshift into a low gear and lock the differentials brings a surprisingly capable dimension of rock crawling prowess to a nimble and quick trail truck.

I also tended to drive the TRX-4 for longer durations when out on the trail, and this had me thinking over the battery capacity I was selecting. Our lightweight 450 and 850 batteries didn’t have the capacity I was looking for, so I started experimenting with the 1500 mAh batteries for a longer running time.

With a dozen trail sessions under our belt, it was time to head into the shop and start making some changes. Again, the goal was not to lose the TRX-4 identity through the upgrade / modification process, but to enhance what it's all about; trail cruising and rock crawling.

|

What Changed

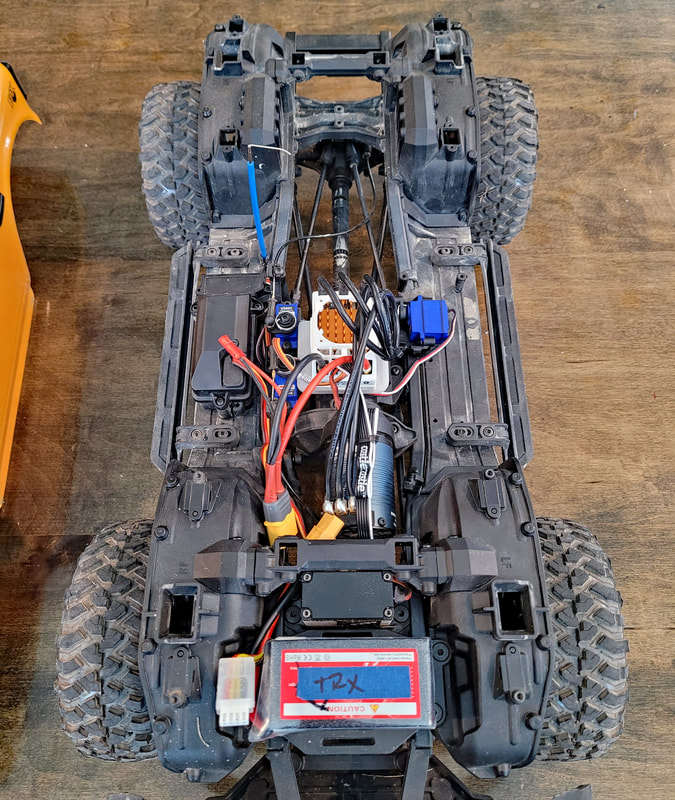

Our plan wasn’t complicated or ingenious by any measure; add weight down low on the axles, adjust the shocks, lower the ride height, update wheels and foams, and then swap out steering servo, motor, and ESC. Pretty standard fare for most crawlers who upgrade their trucks. Starting with the motor and ESC, I had been thinking earlier that a sensored brushless motor for this truck would be the best of both worlds; low-speed control for crawling and high RPMs for sustained trail driving. Modern brushless motors almost maintenance-free, with just the occasional servicing of the bearings being all that's required. While there are quite a few options out on the market, I went with the Castle RC Slate 2280 kV sensored motor and Copperhead 10 ESC. The reason is that this combination has proven both reliable and excellent on the trail in a few of our crawlers already. Along with that, several of our rock racers are also running the Copperhead 10 ESC, so if we feel the need to speed along the U4 track again, the Copperhead will easily handle the request. It was simple enough to fit the motor with a new 11-tooth pinion gear ( OEM is also 11 tooth ) and program the ESC. |

Installing the axle upgrades was relatively straight forward, with just a bit of fitting needed for the brass portal weights. The Global RC brand isn’t known for the same level of quality as Samix, but they are less than half the price and I figured it was worth a try. If I was using the TRX-4 as our main / only crawler, then Samix would have been the choice.

The OEM steering servo took a bit of a beating on the U4 track, so we swapped it out with a JK 45kg servo that was sitting on our shelf. This was only a placeholder until the NSDRC RC 800 V2 servo we had on order arrived.

The shifting servos, transmitter, and receiver were all left as stock from Traxxas. They do a fine job in shifting between gears, locking / unlocking differentials, and replacing the three small servos with premium micro-servos will run about another $200 for something of NSDRC quality. Plus, you have the added fun of programing three more servos to your transmitter; no thanks.

We also swapped out the shocks with an extra set of Axial Capra shocks we had on hand. They were set up with 25wt TLR oil and soft red-band Axial springs. The Traxxas shocks had a slight hangup in their stroke that I couldn't sort out, so I chose to set them aside for the time being. The Axial shocks are close to the same length, and we set the shock collar just a few threads below the top, lowering the ride height to run about a 70% sag, meaning that the shock is 70% compressed with the truck sitting on level ground.

The original battery tray was removed, then we mounted a smaller battery (with velcro) to an aluminum plate sitting just in front of the servo. This is an ideal location for weight distribution, and the area has enough room for a larger 1500 mAh 3s lipo battery. 1500’s lipos are small and light enough to not penalize you with too much weight, yet large enough in capacity for a decent run time. On the trail we see about 1.5 hours per battery.

The motor and servo wiring were left long in that down the road we might move the ESC and transmitter receiver to a different location and didn’t want to end up with wires that were too short. We’ve done that before and ended up regretting that decision (ahem, Kyle).

The OEM steering servo took a bit of a beating on the U4 track, so we swapped it out with a JK 45kg servo that was sitting on our shelf. This was only a placeholder until the NSDRC RC 800 V2 servo we had on order arrived.

The shifting servos, transmitter, and receiver were all left as stock from Traxxas. They do a fine job in shifting between gears, locking / unlocking differentials, and replacing the three small servos with premium micro-servos will run about another $200 for something of NSDRC quality. Plus, you have the added fun of programing three more servos to your transmitter; no thanks.

We also swapped out the shocks with an extra set of Axial Capra shocks we had on hand. They were set up with 25wt TLR oil and soft red-band Axial springs. The Traxxas shocks had a slight hangup in their stroke that I couldn't sort out, so I chose to set them aside for the time being. The Axial shocks are close to the same length, and we set the shock collar just a few threads below the top, lowering the ride height to run about a 70% sag, meaning that the shock is 70% compressed with the truck sitting on level ground.

The original battery tray was removed, then we mounted a smaller battery (with velcro) to an aluminum plate sitting just in front of the servo. This is an ideal location for weight distribution, and the area has enough room for a larger 1500 mAh 3s lipo battery. 1500’s lipos are small and light enough to not penalize you with too much weight, yet large enough in capacity for a decent run time. On the trail we see about 1.5 hours per battery.

The motor and servo wiring were left long in that down the road we might move the ESC and transmitter receiver to a different location and didn’t want to end up with wires that were too short. We’ve done that before and ended up regretting that decision (ahem, Kyle).

|

Along with these changes, we wanted to salvage the Trail Canyon tires and see how they would perform with upgraded foams and beadlock wheels.

The S1 compound on the Trail Canyon tire from Traxxas is their softest rubber and specifically and made for rock crawling. As you know, new tire testing is one of our main interests, and we had already added these tires to the testing schedule when the truck was purchased. To remove the tires, we soaked the tires and wheels in a sealed paint can with 2” of acetone at the bottom. We propped up the tires so they didn’t sit in the liquid acetone, allowing just the vapors to work some magic on the superglue attaching the tires to the plastic wheels. Once the tires came loose ( about two days ), we washed them with warm soapy water, dried them, coated them in a thin layer of silicone oil, and then bagged them up in sealed zip-lock bags for a week. |

After a week of storage, we unpacked the tires, wiped off all remaining silicone oil, and vented with three small holes. For the foams, we used Crawler Innovations 4.5" comp-cut medium two-stage foams in the rear and 4.5" comp-cut soft in the front, mounting the tires onto a set of Injora aluminum beadlock wheels. The rubber felt as good as new, and they looked much better on the deep-dish wheels.

Trail Performance - Modified

Heading back out on the trail with our changes, the TRX-4 felt quite similar to the OEM version, but the tires felt much more planted on steep climbs and sidehills. The brass portal weights significantly lowered the center of gravity on the Bronco, greatly improving the tire's traction. The new two-stage CI foam inserts were far better at allowing the tire to conform to the rock’s surface, resulting in a noticeable sticky, pulling sound as the large tire lugs pulled the truck up steeper sections of trail.

The Castle sensored motor is excellent on the trail, but that’s really not much of a surprise. Castle RC makes quality motors and ESC's for crawling, but it’s about time they come up with a quiet ESC for outrunner motors. We run a number of outrunner motors in our crawlers, and while the torque density in relation to weight savings is outstanding, holy heck they are loud. We didn’t want to mess up the relaxed cruising vibe of the TRX-4 with such a noisy motor, so the Castle Slate brushless motor was the right choice. With low maintenance and solid performance, what's not to like?

Unfortunately, we didn’t account for the wider stance of the wheels and lower ride-height for proper tire clearance. Turning sharp corners while climbing or descending firmly jammed the tire’s lugs into the fender edges, making a horrid sound. It wasn’t a little rub, but a full-on garbage disposal rumble when steering hard into corners.

And there were the factory bumpers. Again, in the looks department they are spot on, but the rear bumper sticks out enough that it catches on the rocks just about every time you turn to crawl up a rock or steep trail. The first few times it didn’t bother me; I chalked it up to an idiosyncrasy of the TRX-4. But after the fiftieth time it caught on a rock, I had enough and decided it was time to replace that part as well.

Heading back out on the trail with our changes, the TRX-4 felt quite similar to the OEM version, but the tires felt much more planted on steep climbs and sidehills. The brass portal weights significantly lowered the center of gravity on the Bronco, greatly improving the tire's traction. The new two-stage CI foam inserts were far better at allowing the tire to conform to the rock’s surface, resulting in a noticeable sticky, pulling sound as the large tire lugs pulled the truck up steeper sections of trail.

The Castle sensored motor is excellent on the trail, but that’s really not much of a surprise. Castle RC makes quality motors and ESC's for crawling, but it’s about time they come up with a quiet ESC for outrunner motors. We run a number of outrunner motors in our crawlers, and while the torque density in relation to weight savings is outstanding, holy heck they are loud. We didn’t want to mess up the relaxed cruising vibe of the TRX-4 with such a noisy motor, so the Castle Slate brushless motor was the right choice. With low maintenance and solid performance, what's not to like?

Unfortunately, we didn’t account for the wider stance of the wheels and lower ride-height for proper tire clearance. Turning sharp corners while climbing or descending firmly jammed the tire’s lugs into the fender edges, making a horrid sound. It wasn’t a little rub, but a full-on garbage disposal rumble when steering hard into corners.

And there were the factory bumpers. Again, in the looks department they are spot on, but the rear bumper sticks out enough that it catches on the rocks just about every time you turn to crawl up a rock or steep trail. The first few times it didn’t bother me; I chalked it up to an idiosyncrasy of the TRX-4. But after the fiftieth time it caught on a rock, I had enough and decided it was time to replace that part as well.

|

More Changes

Back in the shop, we removed the fender flares and trimmed the body to clear the tires. I was a little bummed out about this because the black fender flares look sharp in contrast to the yellow body, but there really wasn’t any way to keep them and clear the tires while maintaining our lowered ride height. The OEM rear bumper was replaced with a fancy aluminum unit from RC4WD, and this new bumper tucked up nicely behind the body. With the bumper designed to be a direct replacement for the OEM unit, the edges of the bumper matched up perfectly with the now removed black fender flares. Without the fender flares present, the TRX-4 looked like it had Mickey Mouse’s ears sticking out the sides. We knocked them off with the grinding wheel, blending the edge with body line. To finish, we dusted the raw aluminum with a bit of black spray paint. |

|

Just for a little fun, we replaced the grey plastic differential covers with bright red aluminum covers. I’m not much of a scale detail guy, but I do like the artistic touch they have. It's also not sprung weight, so I can further justify it in my mind.

It was hard to stop the modifications at this point. Usually, we change out the shock towers, links, rear link riser, Panhard mount ( that may still happen ), as well as shaving non-essential sprung weight wherever possible. But we didn't, and stayed true to the goal of keeping the TRX-4 feeling and driving like a TRX-4. With that decision, we put the pencil down and headed back out to the trail. |

|

Back at Badrock Ridge

As you all guessed, we headed back out to Badrock Ridge with what we felt could be the final iteration for our TRX-4. Granted the aftermarket options and upgrades are seeming endless (and highly tempting), I feel the narrow focus of our approach has kept the TRX-4 feeling close to its original form. Tackling some of the trails which had given us trouble earlier proved that clearing the rear bumper and not digging the tires into the fenders helped quite a bit. Over the next few weeks, we explored new areas at Badrock Ridge, pushing some of the sessions well past the three-hour mark. This extended time allowed us to really develop a feel for the truck and its climbing characteristics, learning just how far we could push capabilities without damaging the body. |

|

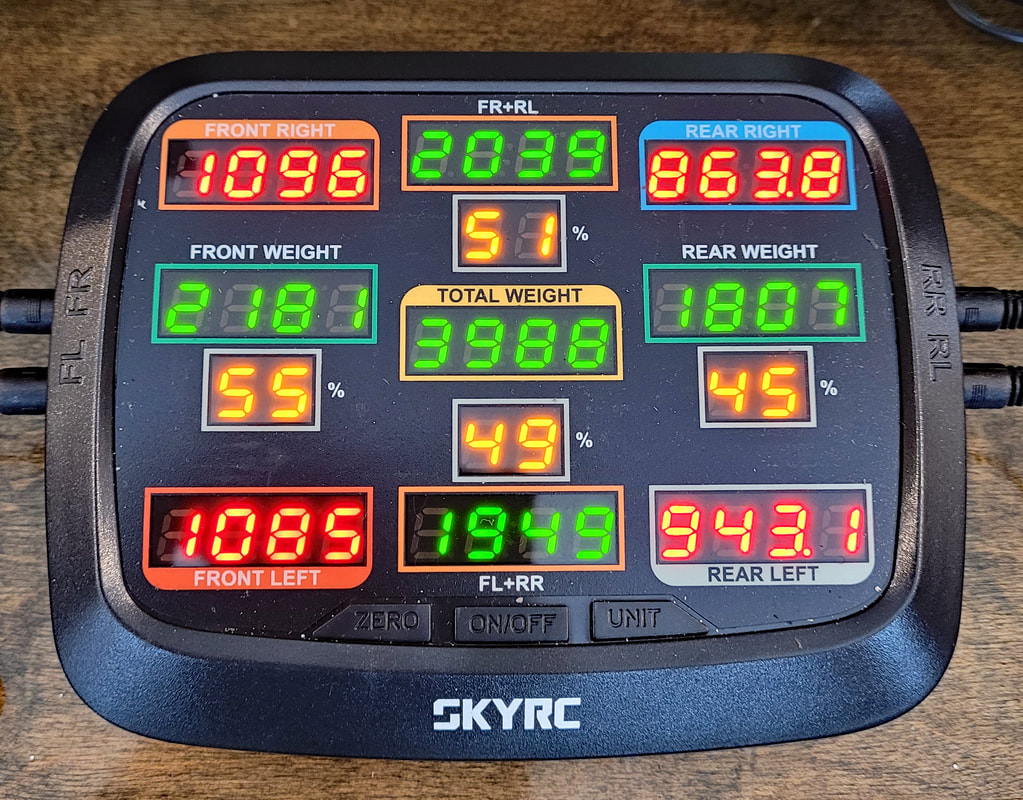

It seemed that on steep, slick sandstone climbs, the TRX-4 would settle into a rhythm and keep turning the tires while gradually gaining elevation. The balance was such that just before the front tires would lift completely off the rock, the rear tires would begin to slip.

In my opinion, this is a near perfect balance for a trail truck’s weight distribution in relation to the tire’s traction. The weight down low on the axle also gave us an edge over the OEM setup when dealing with tricky sidehill situations. As before, a few trails which were a bit too steep on the sidehill are now doable with the heavier weight setup. At times, the leaning TRX-4 would raise the stress level a bit, but it seemed to have just enough composure to pull through and keep all four tires stuck to the rock. |

|

|

As for the Trail Canyon tires, changing to proper foams and wheels allowed the tires to conform to the rock much more, giving superb traction on the tougher sections of trail.

Our initial impression of the tires is quite favorable, but we will be doing a much deeper dive into these tires later this summer. Posted here is a short clip of how the tires grip on this eroded piece of slick sandstone. |

|

Final Thoughts

Choosing the Traxxas TRX-4 2021 Bronco to be our “standard trail truck” for tire testing has proven to be a good decision. It’s easily the most well-rounded truck in the fleet, and its sharp looks stand out on the trail during photo shoots. The handful of upgraded parts hasn’t diminished the feel of its original character, but rather it takes the TRX-4’s capability up a few notches on steep and technical terrain. We’re also kicking around the idea of how to update a few of the older tire reviews with new results from the TRX-4, but the exact path forward is still up in the air. |

|

As of this writing, we’ve spent about 30 hours driving the TRX-4, and it seems to be equally at home cruising along the trail as it is scaling steep rock formations.

While I’m somewhat reluctant to say this, I think this version of the TRX-4 might be the trail truck / crawler to have in your collection if you only have room for one. It won't pull the same steep lines that some of our other trucks can handle, but its versatility and "realness" is something we find special. The reliability has been excellent and the performance admirable in just about every situation we’ve encountered. |

|

Build List

*We recently installed the under-drive gearing after our initial evaluation, and it does improve the steep crawling performance while not overly impacting casual trail driving. |